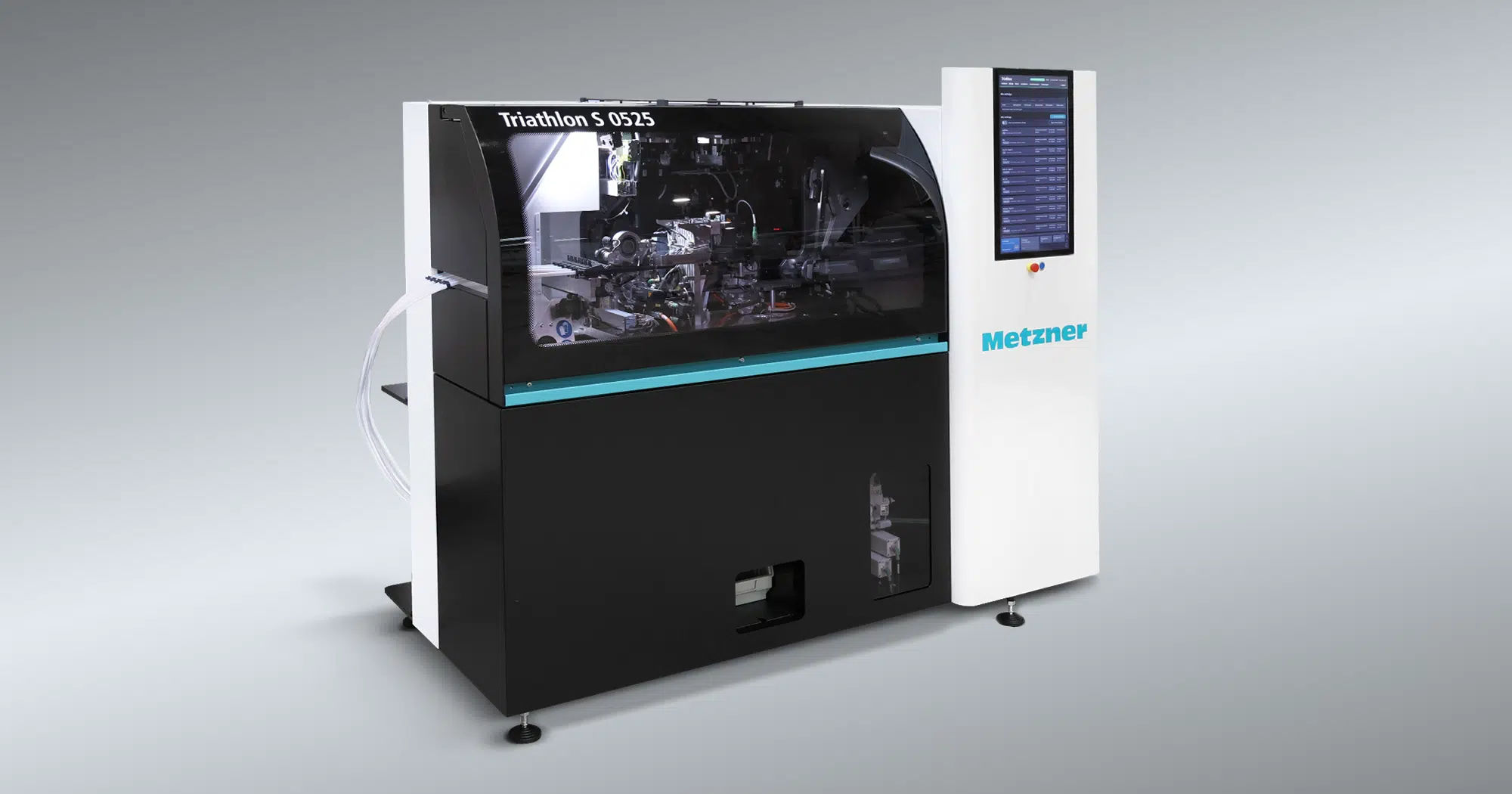

Metzner Triathlon S 0525/1060

More efficiency and cost savings in control cabinet construction, even for small series

Automatic wire change:

12-fold

Wire output:

chain bundle and/or wire rails

Max. number of wire rails:

5 pcs.

Cycle time: 11 s

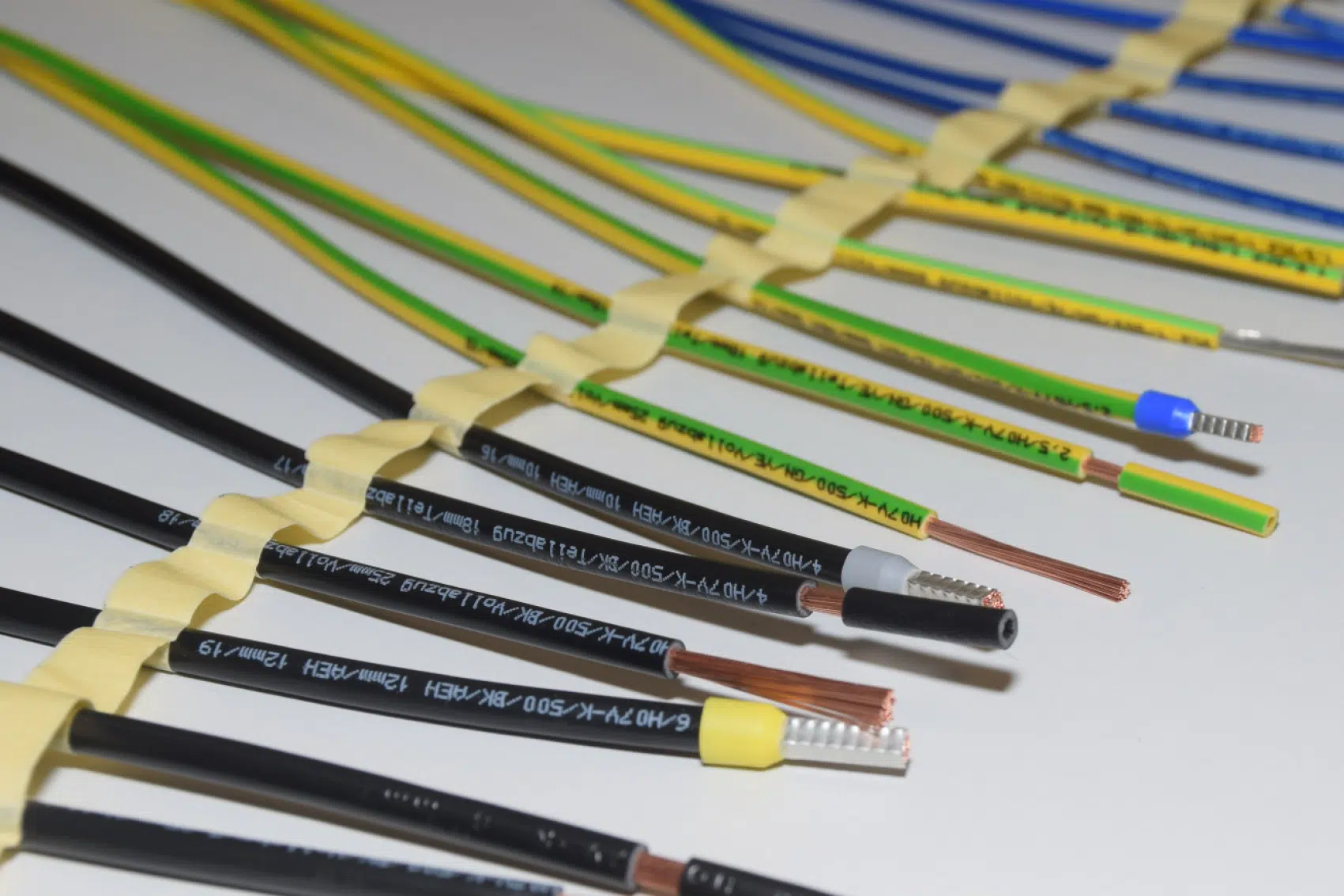

1. Wire output as cable bundles or in ducts: always in the correct order!

The produced wires are optionally placed either between two adhesive tapes as cable bundles with different cross-sections from 0.5 mm² to 6 mm² or in wire ducts. No matter which output form you choose, the wires are always arranged according to the sequence required for control cabinet wiring. For wire output in ducts, each cross-section is placed in a separate wire duct, and after the processing is complete, the wire ducts are removed from the machine and, with an optionally available transport trolley, delivered directly to the workstation for wiring. The removal takes place in the predefined order without removing the adhesive tape.

Control cabinet manufacturing: efficient, fast, fully automatic

Features & Benefits

- Fully automatic wire processing without personnel

- Automatic wire change for up to 12 wires

- Production of 300 wires per hour

- Average wire length 1500 mm with ferrules on both ends

- Wire output as cable bundles or in wire ducts (max. 5 pieces)

- Automatic wire labeling with source/target marking

- Fast, tool-free change of wire cassette in approx. 30 seconds

- Efficient processing of cross-sections from 0.5 mm² to 6 mm²

- Automatic crimping with 5 or 10 feed pots

- Intelligent wire storage as accessory, with quick-change capability

Applications

- Cutting stranded and solid wires (0.5 – 6 mm²)

- Stripping with full pull-off (2–22 mm) and partial pull-off (6–20 mm)

- Stripping multi-core cables

- Stripping flat ribbon cables

- Crimping ferrules (8–18 mm) without tool change

- Stripping extremely fine strands

- Cutting wires up to 7,000 mm

- Printing and marking wires with source/target

Technical Data

| Performance Overview / Triathlon Models | TRIATHLON S 0525 | TRIATHLON S 1060 |

|---|---|---|

| Wire cross-section | 0.5 – 2.5 mm² | 0.5 – 6 mm² |

| Wire diameter | 1.5 – 4.0 mm | 1.5 – 5.5 mm |

| Automatic wire change | 12 wires | 12 wires |

| Automatic ferrule change | 5 | 10 |

| Wire output sequential | Bundle or rail system | Bundle or rail system |

| Max. number of wire rails | up to 5 pcs. | up to 5 pcs. |

| Printing | 1 or 2 Ink-Jet | 1 or 2 Ink-Jet |

| Data import | XLSX, CSV, TXT | XLSX, CSV, TXT |

| Shortest wire length | 150 mm | 150 mm |

| Longest wire length | 7,000 mm | 7,000 mm |

| Stripping length | up to 22 mm | up to 22 mm |

| Ferrule length | 8 – 18 mm | 8 – 18 mm |

| Partial strip | 6 – 20 mm | 6 – 20 mm |

| Full strip | 2 – 22 mm | 2 – 22 mm |

| Cycle time with ferrule both sides | 11 sec. | 11 sec. |

| Operating voltage | 230 V, 1~, 50 Hz/60 Hz | 230 V, 1~, 50 Hz/60 Hz |

| Power consumption (approx.) | 1 kW | 1 kW |

| Compressed air connection | min. 6 bar, max. 10 bar | min. 6 bar, max. 10 bar |

| Dimensions (L x W x H) | 2,170 mm x 1,080 mm x 1,870 mm | 2,170 mm x 1,080 mm x 1,870 mm |

| Weight | 800 kg | 800 kg |

Performance Overview / Triathlon Models

Wire cross-sectionTRIATHLON S 0525: 0.5 – 2.5 mm² / TRIATHLON S 1060: 0.5 – 6 mm²

Wire diameterTRIATHLON S 0525: 1.5 – 4.0 mm / TRIATHLON S 1060: 1.5 – 5.5 mm

Automatic wire change12 wires

Automatic ferrule changeTRIATHLON S 0525: 5 / TRIATHLON S 1060: 10

Wire output sequentialBundle or rail system

Max. number of wire railsup to 5 pcs.

Printing1 or 2 Ink-Jet

Data importXLSX, CSV, TXT

Shortest wire length150 mm

Longest wire length7,000 mm

Stripping lengthup to 22 mm

Ferrule length8 – 18 mm

Partial strip6 – 20 mm

Full strip2 – 22 mm

Cycle time with ferrule both sides11 sec.

Operating voltage230 V, 1~, 50 Hz/60 Hz

Power consumption (approx.)1 kW

Compressed air connectionmin. 6 bar, max. 10 bar

Dimensions (L x W x H)2,170 mm x 1,080 mm x 1,870 mm

Weight800 kg

2. Automatic wire labeling with source/target marking

Modern ink-jet printers label the wires with excellent readability and automatically select the correct contrast color based on the wire color. The labeling takes place automatically during the process, without any time loss and without additional drying times. The labeling can optionally be applied at adjustable positions or continuously along the wire.

3. Automatic crimping unit with 5 or 10 feed pots

The feed pots (5 or 10) in the cross-section range from 0.5 mm² to 6 mm² are selected according to customer requirements and automatically process loose ferrules with a length of 8 mm to 18 mm using a Quattro crimping tool, without any retooling. The ferrules processed comply with DIN 46228. In addition to ferrule crimping, the wires can also be output with full pull-off from 2 mm to 22 mm or partial pull-off from 6 mm to 20 mm.

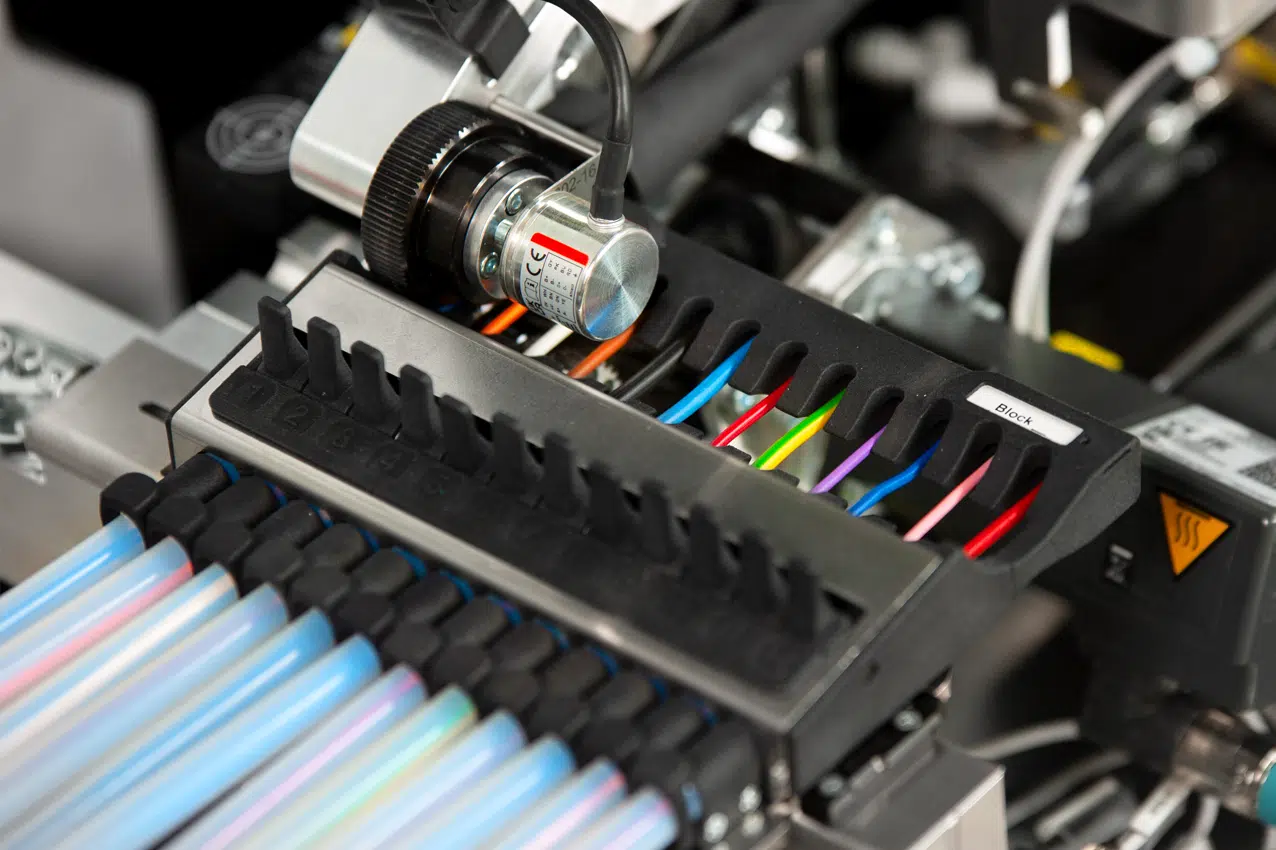

4. Automatic wire change

The automatic wire change for all wires required in a control cabinet project is the prerequisite for wire output according to the wiring sequence. The Triathlon S offers automatic wire change for 12 wires, and the Triathlon L for up to 36 wires. Each quickly changeable wire cassette holds 12 wires, which are read by the Triathlon machines via an RFID chip and processed automatically. The Triathlon L is designed to accommodate 3 cassettes with 12 wires each simultaneously, and the Triathlon S for 1 cassette with 12 wires. In both machines, the cassettes are changed without tools in approximately 30 seconds. The machine automatically recognizes the wires and independently adjusts all processing parameters for the new wires.5. Automatic wire change

The automatic wire change for all wires required in a control cabinet project is the prerequisite for wire output according to the wiring sequence. The Triathlon S offers automatic wire change for 12 wires, and the Triathlon L for up to 36 wires. Each quickly changeable wire cassette holds 12 wires, which are read by the Triathlon machines via an RFID chip and processed automatically. The Triathlon L is designed to accommodate 3 cassettes with 12 wires each simultaneously, and the Triathlon S for 1 cassette with 12 wires. In both machines, the cassettes are changed without tools in approximately 30 secon

6. Additional savings

By outputting the wires in the wiring sequence and automatically labeling each wire, the assembler can identify the source and destination of a wire without further checking the circuit diagram. With output in wiring sequence, the position of the source is also automatically predefined. This reduces errors and simultaneously achieves further significant savings in wiring, which additionally improves the ROI considerations mentioned at the beginning.