PREFEEDER PF 200 FAMILY

automatic, tension-free cable feeding

Built to adapt – fewer limits, more options

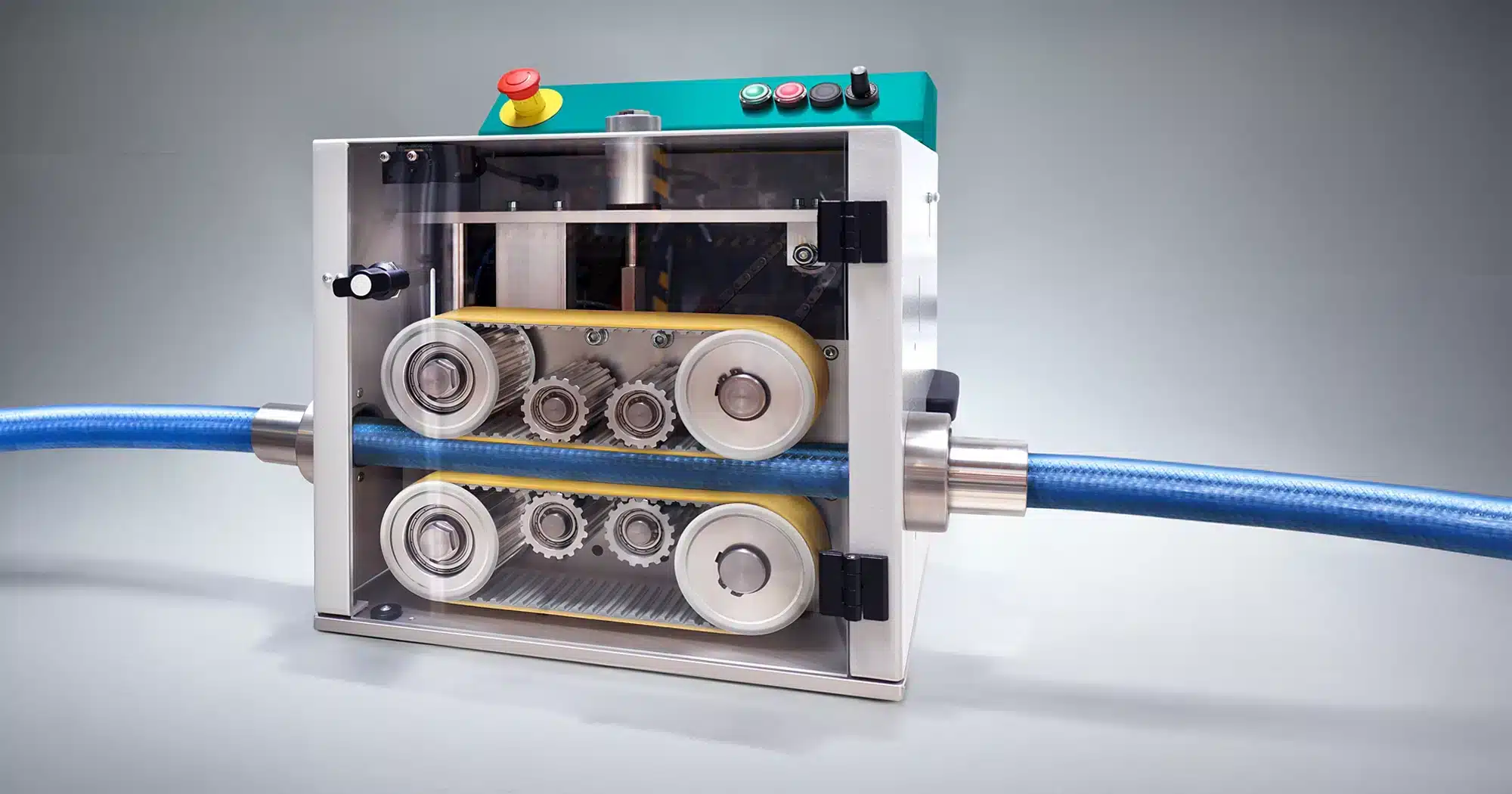

The Prefeeder PF 200 can be placed either freestanding or rack-mounted in front of a cable processing machine. Its powerful electrical drive ensures smooth tension-free cable feeding directly from a cable reel. The pneumatic puller opens and closes automatically and adjusts to the cable diameter, providing constant, slip-free traction.

Highlights

- 4 Base units

- 5 Speed controllers

- Unmatched flexibility

- The perfect solution for your production requirements

- Works best with Metzner – yet equipped to work with all brands of cut&strip machines

- Top-of-the-line features at a surprisingly affordable price

Applications

- Feeding cables, tubes, and profiles made of plastic or rubber into processing machines

- Ensuring tension-free delivery from passive reels or spoolers

- Supporting cutting, stripping, printing, or measuring systems with consistent material flow

- Managing elastic or delicate materials that require controlled handling

- Integration into semi-automated and fully automated production lines

- Ideal for high-speed applications with variable cable types and diameters

Technical data

| PF200 LR 3~ | PF200 LR SERVO | PF200 RL 3~ | PF200 RL SERVO | |

|---|---|---|---|---|

| Material diameter max. | 38 mm (1.49”) | |||

| Pulling force | 150 N | 240 N | 150 N | 240 N |

| Feed speed | 0 – 1.35 m/s | 2.7 m/s | 0 – 1.35 m/s | 2.7 m/s |

| Drive | 3~ drive | Servo drive | 3~ drive | Servo drive |

| Operating direction | left to right ⇒ | right to left ⇐ | ||

| Contact length | 210 mm | |||

| Compressed air connection | 4 – 6 bar (60 – 90 psi) | |||

| Weight (w/o speed control) | 44 kg | |||

| Dimensions (L × W × H) w/o speed control device | 55 × 43 × 44 cm (21.5“ x 1.5“ x 17.3“) | |||

| Pedestal (feeding height 1090 mm) | optional | |||

| Power supply | 230 V / 50-60 Hz (opt. 110 V) | |||

Lower investment.

Less complexity.

Happier teams.

precision & system flexibility

PREFEEDER PF 200 FAMILY

MODULAR. POWERFUL. PERFECTLY ALIGNED.

The Metzner Config Formula:

4 Base units

× 5 Speed controllers

= Endless possibilities

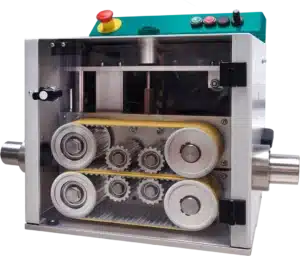

PREFEEDER PF 200

Base unit available with servo drive, 3-phase drive

and two operating direction.

Technical data

| DANCING ARM SMALL | DANCING ARM LARGE | CUBE ACCUMULATOR | CUBE ACCUMULATOR + SOFT START | LOOP CONTROL | |

|---|---|---|---|---|---|

| Material diameter max. | 18 mm (0.7″) | 35 mm (1.38”) | |||

| Weight impact on feed material | ~25 g+, adjustable | ~200 g+, adjustable | |||

| Arm length (from nozzle) | 70 cm | 65.5 cm | – | ||

| Dimensions incl. prefeeder (L × W × H) | 140 × 56 × 140 cm | 209 × 56 × 140 cm | 41 × 31 × 104 cm | ||

| Accumulation volume | ~1.5 m | 900 mm (1 loop) | up to 3 loops | ~1.5 m | |

from start to smart: scalable. seamless. metzner.

PREFEEDER PF 200 FAMILY

select. combine. optimize!

Seamlessly integrates into complete Metzner production lines – illustrated by two examples of fully automated wire processing systems.

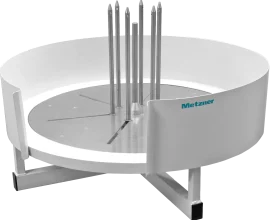

Cable Dereeler

DRS 3.1000

Prefeeder PF 200

with small dancing arm + pedestal

Cable processing machine

AM 2850

Active cable storage unit

MA 2000

Cable Dereeler

DRS 1.800

Loop Control

DHS 1000

Prefeeder PF 200

with extra pedestal

Corrugated tube processing

machine CT 4200

Collection

Box