PREFEEDER FAMILY PF200

MAXIMUM CONTROL FOR MODERN PRODUCTION LINES

Built to adapt – fewer limits, more options

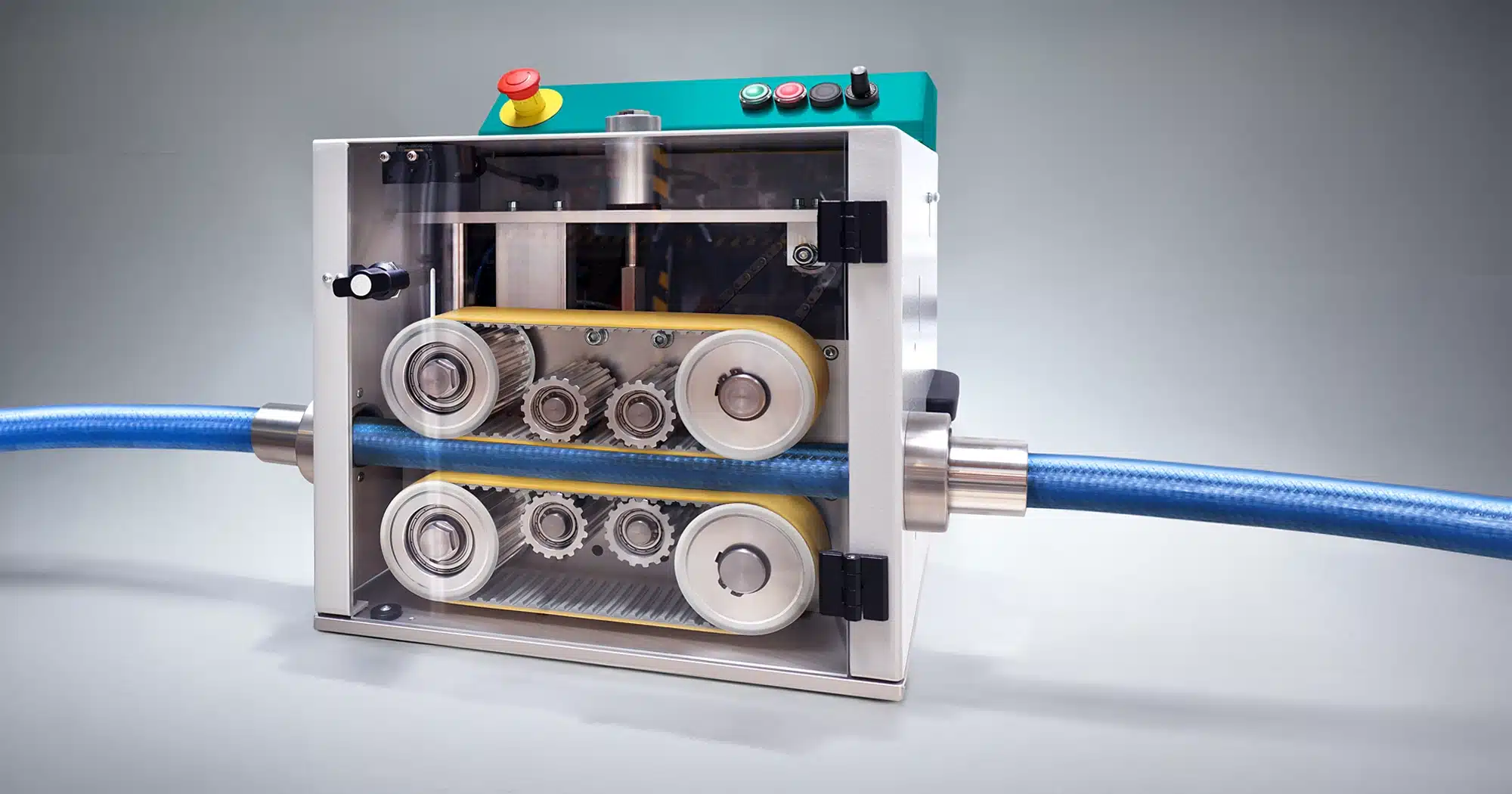

The PF200 is a high-performance, electrically driven prefeeder that reliably pulls cables and flexible materials from passive reels or spools – with zero tension and full process control. Feed speed automatically adapts via the integrated dancing arm or an optional Metzner loop control system, ensuring precise synchronization with downstream machines.

Ideal for heavier reels and materials up to 38 mm (1.49″) in diameter, the PF200 handles even challenging cable types with ease. With pulling forces up to 240 N and feed speeds up to 2.7 m/s, it supports both delicate and high-throughput applications. The PF200 is available with either a 3-phase or servo drive, and can be configured for left-to-right or right-to-left operation. Compact, easy to handle, and CE-compliant – the PF200 is your flexible solution for reliable feeding performance.

Highlights

- Widest range of options

- Superior torque & feed speed

- Perfectly synchronized servo clamp (Metzner exclusive)

- Works best with Metzner – yet equipped to work with all brands of cut&strip machines

- Top-of-the-line features at a surprisingly affordable price

Applications

- Feeding cables, tubes, and profiles made of plastic or rubber into processing machines

- Ensuring tension-free delivery from passive reels or spoolers

- Supporting cutting, stripping, printing, or measuring systems with consistent material flow

- Managing elastic or delicate materials that require controlled handling

- Integration into semi-automated and fully automated production lines

Ideal for high-speed applications with variable cable types and diameters

Technical data

| FUNKTION | PF200 LR 3~ | PF200 LR SERVO | PF200 RL 3~ | PF200 RL SERVO |

|---|---|---|---|---|

| Material diameter max. | 38 mm (1.49”) | |||

| Pulling force | 150 N | 240 N | 150 N | 240 N |

| Feed speed | 0 – 1.35 m/s | 2.7 m/s | 0 – 1.35 m/s | 2.7 m/s |

| Drive | 3~ drive | Servo drive | 3~ drive | Servo drive |

| Operating direction | left to right ⇒ | right to left ⇐ | ||

| Contact length | 210 mm | |||

| Compressed air connection | 4 – 6 bar (60 – 90 psi) | |||

| Weight w/o speed control device | 44 kg | |||

| Dimensions (L × W × H) | 55 × 43 × 44 cm | |||

| Pedestal (feeding height 1090mm) | optional | |||

| Power supply | 230 V / 50-60 Hz (opt. 110 V) | |||

Lower investment.

Less complexity.

Happier teams.

precision & system flexibility

Discover the freedom of the PF200 Prefeeder Family – engineered for your success.

Tired of fixed solutions that restrict workflow and inflate costs? The modular PF200 system from Metzner is your answer. With four base units and five intelligent controllers, you build exactly what you need – no more, no less. Each setup adapts to your cable, your process, and your pace. Fully CE-compliant, the PF200 meets all mechanical and electrical safety requirements. If there’s doubt about your application, simply submit a wire sample – we’ll ensure the perfect fit.

From stand-alone use to full automation, the PF200 connects seamlessly with Metzner systems – no rework, no reprogramming. Whether cutting, stripping or marking: Each unit is compatible with Metzner software and hardware and can be swapped or scaled to your process. A solution that evolves with your production. For high-speed controllers like SoftStart Inlet or Cable Accumulator, the robust pedestal stand ensures stability and precision – exactly where it counts.

Cut costs, boost efficiency, and keep your team happy – with a modular system that grows with your business and streamlines your workflow. No more compromises: Metzner’s smart system logic lets you build a setup as individual as your process. Forget rigid systems. Trust in a platform built for long-term flexibility, speed, and simplicity – all from one source.

PREFEEDER FAMILY PF200

MODULAR. POWERFUL. PERFECTLY ALIGNED.

The Metzner Config Formula:

4 Base units

× 5 Speed controllers

= Endless possibilities

PREFEEDER PF200

Different base units with 3-phase or servo drive

and left or right feed direction.

Technical data

| FUNCTIONS | DANCING ARM SMALL | DANCING ARM LARGE | CUBE ACCUMULATOR | CUBE ACCUMULATOR + SOFT START | LOOP CONTROL |

|---|---|---|---|---|---|

| Material diameter max. | 18 mm (0.7“) | 35 mm (1.38”) | |||

| Weight impact on feed material | ~25 g+, adjustable | ~200 g+, adjustable | ~200 g+, adjustable | ||

| Arm length (from nozzle) | 70 cm | 65.5 cm | – | ||

| Dimensions incl. prefeeder (L × W × H) | 140 × 56 × 140 cm | 209 × 56 × 140 cm | 41 × 31 × 104 cm | ||

| Accumulation volume | ~1.5 m | 900 mm (1 loop); up to 3 loops | ~1.5 m | ||

The Power Behind the Cut. scalable. seamless. metzner.

PREFEEDER FAMILY PF200

select. combine. optimize!

FROM START TO SMART: Seamlessly integrates into complete Metzner production lines – illustrated by two examples of fully automated wire processing systems.

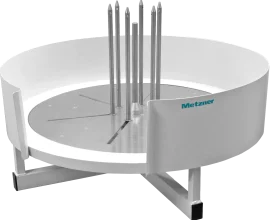

Cable Dereeler

DRS 3.1000

Prefeeder PF 200 with small dancing arm

and extra pedestal

Wire processing machine

AM2850

Active cable storage unit

MA 2000

Cable Dereeler

DRS 1.800

Loop

Control

Prefeeder PF 200

with extra pedestal

Corrugated tube processing

machine CT4200

Collection

Box