AUTOMATED PRODUCTION OF CATHETER TUBES

The machine exactely cuts catheter tubes and safely removes the mandrel inside the tube

An internationally active medical technology company that produces and sells catheter tubes, among other things, has optimized its manufacturing process with the help of an automated catheter manufacturing line from Metzner Maschinenbau.

With Metzner’s know-how, it was possible to replace a costly manual process with an automatic machine, saving costs. At the same time, the length accuracy and the cutting quality were significantly improved.

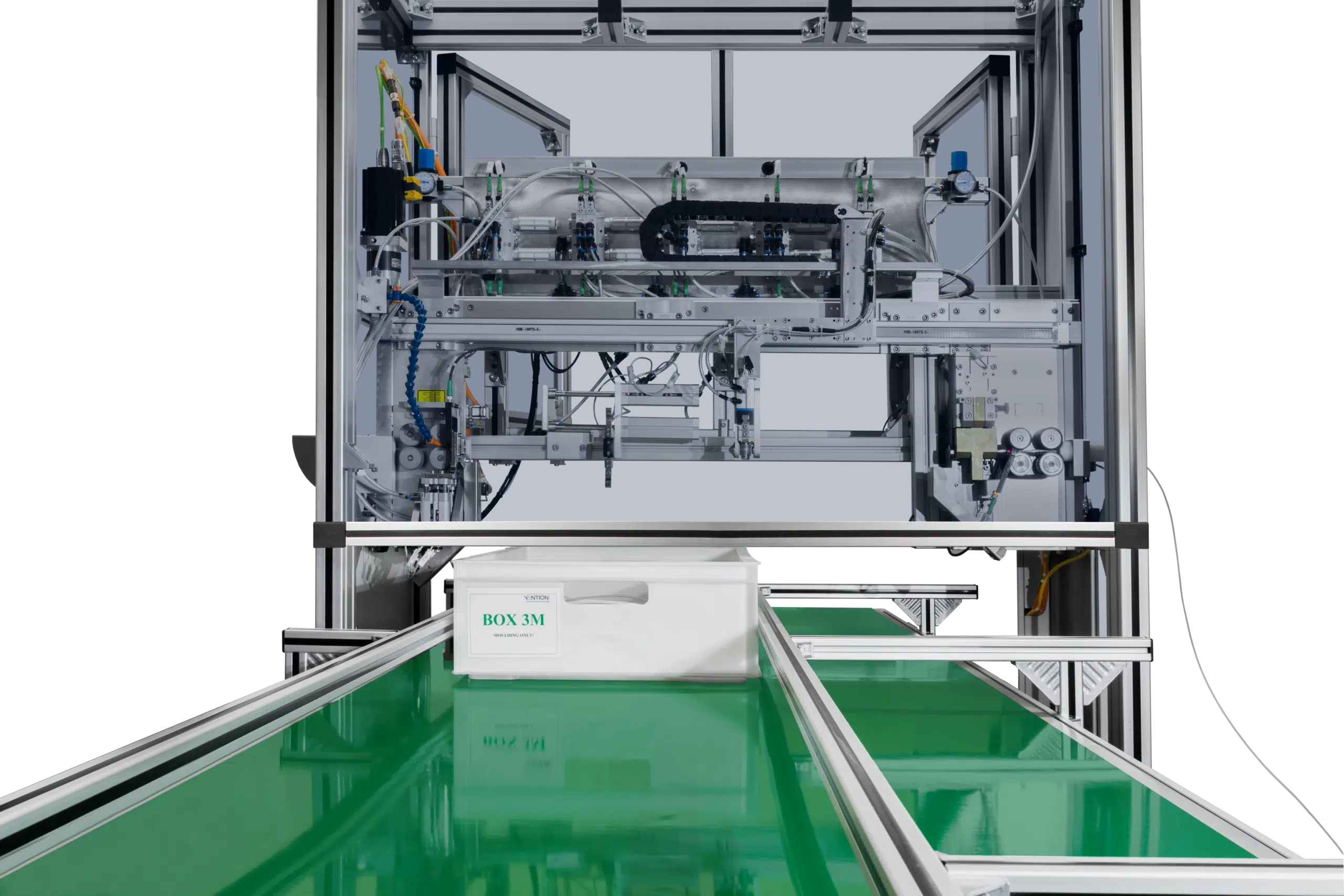

The company supplied an automatic system that precisely cuts the catheter tubing to length, removes the mandrel present from the extrusion without leaving any residue and without longitudinal expansion, and then deposits the tubing in a collecting container at the end.

APPLICATIONS

This customized, automated catheter manufacturing line produces high quality catheters:

- Automatic feeding of the cutting-unit

- Exact cut-to-length of the catheters

- Residuee-free removing of the mandrels

- Optimal filling of the collection containers with the finished catheters

- Sensor-controlled changing device for the collection containers

So, the system works autonomously for 4 to 6 hours.

Your customized solution

When it comes to producing tubes, pipettes, cathethers and similar products for medical devices, Metzner only know solutions. How can we help you to increase your production quality even further and save costs in the process. Put us to the test: