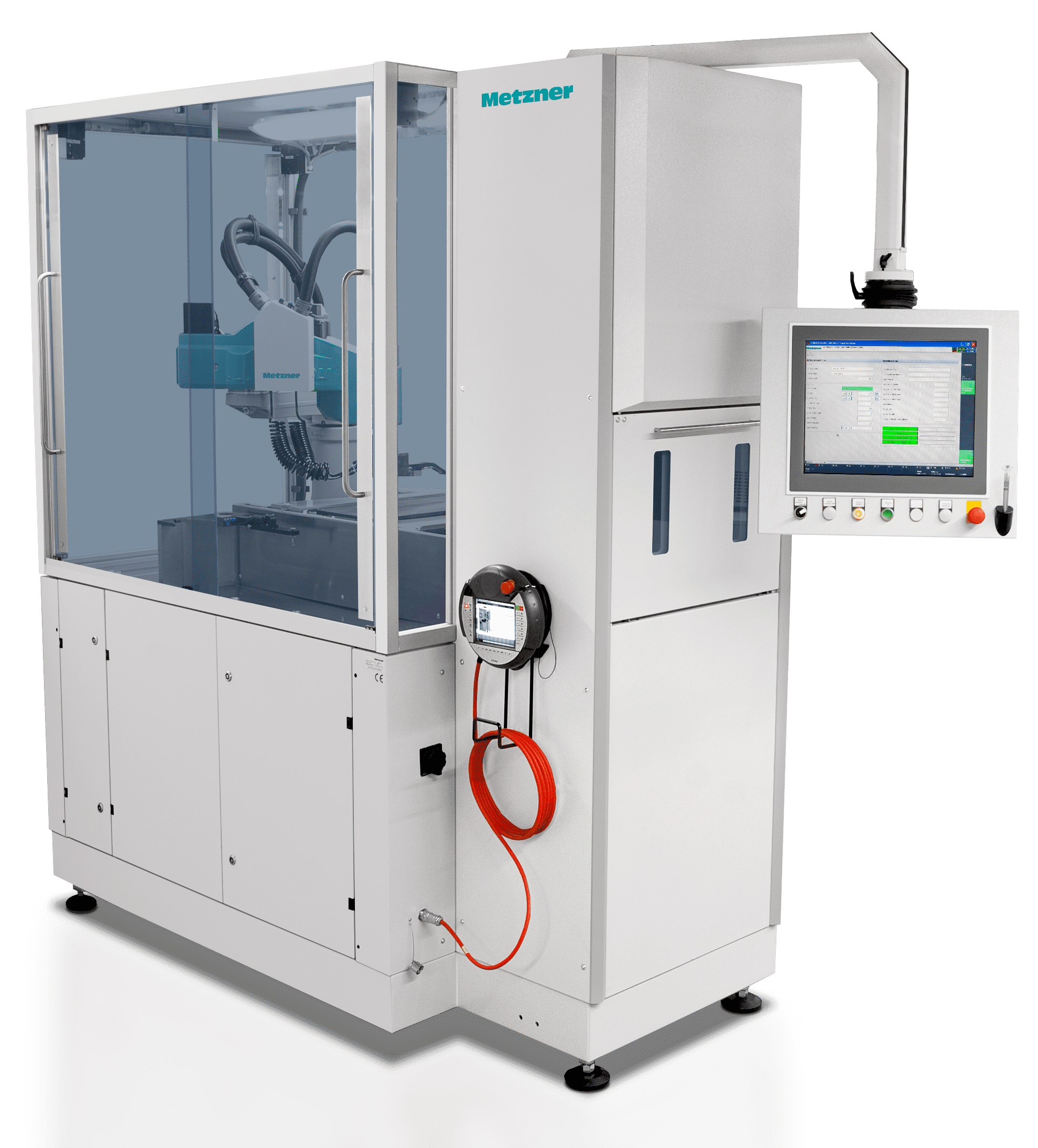

METZNER RPA-10SL: THE COMFORTABLE WAY

Press automation for medium to large lot sizes: Metzner RPA 10-SL

The Metzner RPA 10-S has an integrated magazine system for up to ten sintering plates with automatic sintering plate change. So, it automatically removes empty sintering plates from the magazine, loads them and then returns them. Thanks to the sintering plate change automation, the powder press automation works independently over a longer period of time, without loading and unloading processes leading to a press stop. Weighing or deburring of the pressed parts is also fully automatic.

With the integrated 4-axis SCARA robot, the machine achieves very high system speeds of up to 30 strokes/min. This makes it ideally suited for connection to electric presses with high cycle rates.

This sintering plate change automation is conveniently operated via the integrated control system or the mobile operating terminal.

TECHNICAL DATA

| Performance data | RPA 10-SL |

| Storage capacity: Empty sinter trays | 10 |

| Storage capacity: Loaded sinter trays | 10 |

| Sinter tray changing time | approx. 5 sec. |

| Sinter tray size | max. 400 mm x 300 mm x 65 mm | 1’4″ x 11.8″ x 2.6″ |

| Sinter tray design | common designs |

| Performance references: pick & place | 30 parts/min. |

| Performance references: pick & place with deburring | 18 parts/min. |

| Speed | up to 2 m/sec. | 6’7″/sec. |

| Repeatability | +/- 0.05 mm | 0.002″ |

| Mounting | Mounting bracket |

| Machine parameters | |

| Power supply | 3~400 V, 50/60 Hz, 32 A or transformator |

| Drive | electronic |

| Compressed air supply | 6 bar | 87 PSI |

| Dimensions | 2,100 mm x 1,050 mm x 2,500 mm | 6’11” x 3’5″ x 8’2″ |

| Weight | 1,300 kg | 2,866 lbs |

| Optional equipment | |

| Gripper changing system |  |

| Gripper system | option |

| Cleaning system | option |

| Display | Touch 19″ colour |

| Weighing system | option |

| Pneumatic deburring | option |

| Mechanical deburring | option |