METZNER AM 1000: REDEFINING THE COMPACT CLASS

The AM 1000 fully industrial-professional compact cut-and-strip machine

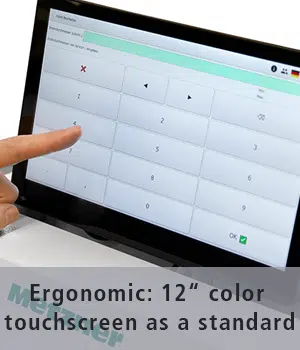

As standard

12" colour touchscreen

Software integrated

At no extra costs: MES, part list, PC integration and much more

Toolfree change over

of blades and guides

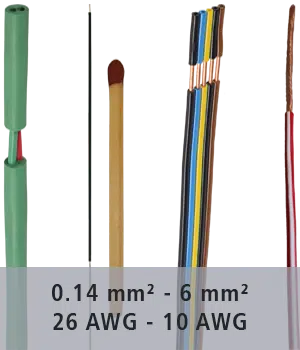

For cross sections

from 0.14 mm² to 6 mm² | 26 AWG to 10 AWG

Previous

Next

Although the Metzner AM 1000 cut and strip machine is our smallest model, this cable processing machine is ideally equipped for your professional requirements. This is true both for the processing options and the interfaces for the entire range of peripheral devices. An excellent software package is also included as standard.

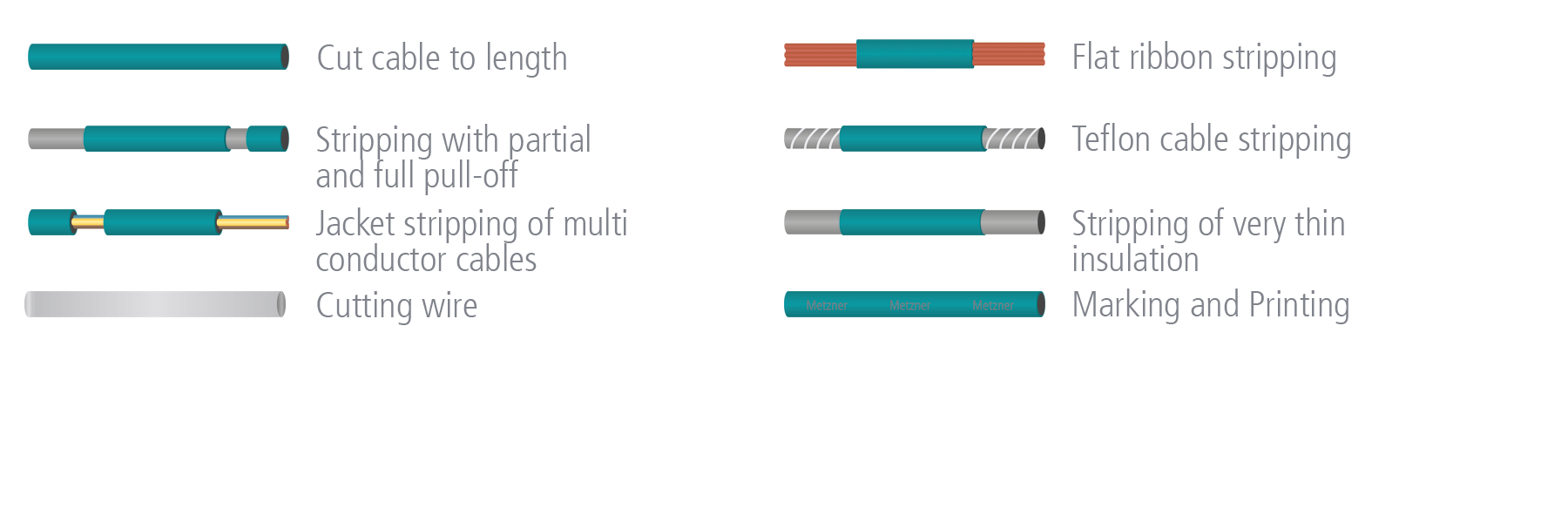

APPLICATIONS

The Metzner AM 1000 can perform these tasks for you:

TECHNICAL DATA

| Functions/Programs | AM 1000 |

| Cutting to length |  |

| Stripping with full pull-off |  |

| Stripping with partial pull-off |  |

| Stripping in multiple steps |  |

| Slitting | – |

| Multiple stripping | – |

| Flat cables | ≤ 10 mm width (option) |

| Material end detection | option |

| Cable length correction |  |

| Recipe data management |  |

| Length measurement system | option |

| Machine Parameters | |

| Transport unit | roll |

| Networking / MES interface (Industry 4.0) | selectable |

| Remote maintenance |  (PC integrated) |

| Cable cross section stranded conductor | 0.14 mm² – 6 mm² | 26 AWG – 10 AWG |

| Max. outer diameter | 9 mm | 0.35″ |

| Cable length | 35 mm – 999 m | 1.38″ – 3,278′ |

| Max. Cable transport speed | 220 m/min. | 722 ft/min. |

| Max. Stripping length full stripping | 1st side: 40 mm – 120 mm | 1.57″ – 4.72″ 2nd side: 0 mm – 30 mm | 0″ – 1.18″ |

| USB/Ethernet |  |

| Electrical connection | 230V; 50 Hz or with transformer |

| Pneumatic connection | 6 bar |

| Dimensions (L x W x H) | 390 mm x 600 mm x 370 mm | 15.4″ x 23.6″ x 14.6″ 390 mm x 600 mm x 540 mm | 15.4″ x 23.6″ x 21.3″ (with PC on top) |

| Weight | 28 kg |

| Rotary cutting unit | – |

| Screen | 12″ touchscreen; tiltable |

Outstanding processing possibilities thanks to a wide range of cross-sections: Cut and strip machine Metzner AM 1000

On the one hand, our Metzner AM 1000 has the necessary sensitivity to process cables with a cross-section of 0.14 mm² | AWG 26. On the other hand, the cable cutting machine has the capacity for 6.0 mm² cable cross-sections (AWG 10). It also cuts and assembles flat ribbon and Teflon cables.

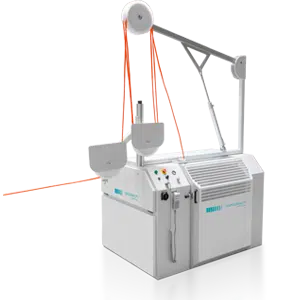

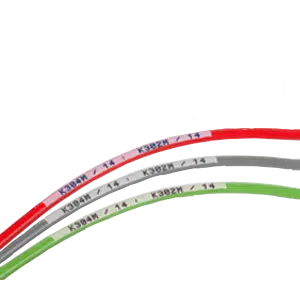

Naturally, the Metzner AM 1000 has a complete set of interfaces. This means that the cable cut and strip machine is prepared for a variety of feeding devices as well as winders and stackers. As it is also prepared for various printing technologies, you can transform the table model into a fully equipped processing line.

Of course, Metzner has also thought about user-friendliness. The Metzner AM 1000 is equipped with a tilting 12″ color touchscreen as standard. The graphical user interface is also identical to the other machines. This means you do not have to retrain your team. The software for creating the cable list also comes as standard.