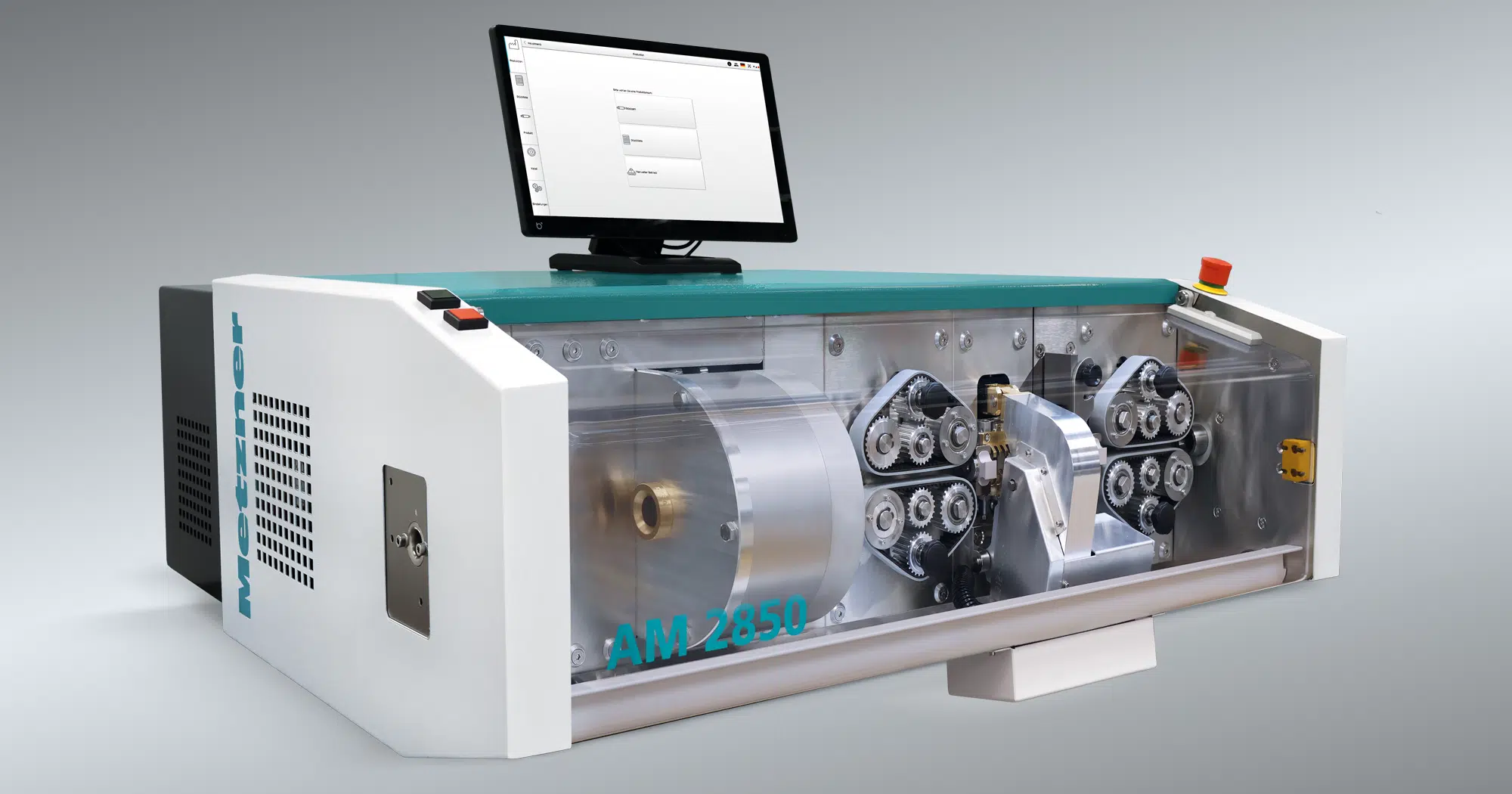

Metzner AM 2800 SAW/AM 2850 SAW

Maximum versatility and power for cables up to 15 mm Ø and 35 mm²

Integriertes Sägemodul

programmierbar über HMI für Sägevorschub und Drehzahl

Vollautomatische saubere Sägeschnitte

ohne Nachbearbeitung

Quetschfreie, rechtwinklige Schnitte

für Sucoform-, Sucoflex- und POF-Kabel

Rotativmodul plus Sägeschnitt

für maximale Bearbeitungsflexibilität

Previous

Next

With saw module for demanding cable processing

Precise Cutting and Stripping with Saw Cut

The Metzner AM 2000 SAW series expands the proven AM 2000 lineup with fully integrated saw modules for precise cable cutting, especially for cables that are difficult to process with conventional blade sets. All machines operate fully automatically and are equipped with state-of-the-art software that sets the saw cut position, blade speed, and feed rate as parameters – ensuring consistently precise results and the highest production quality.

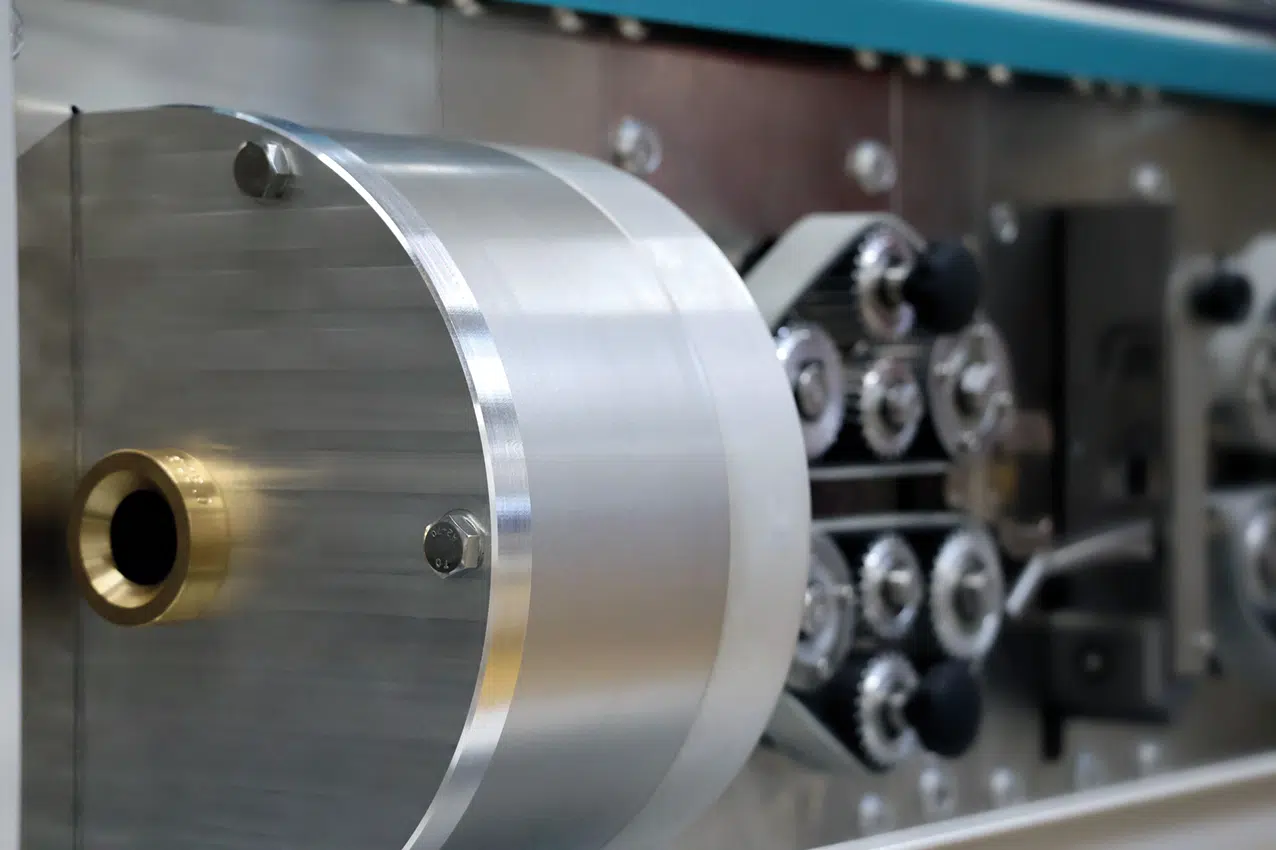

Double-Blade and Saw Module for Standard Applications

Both machines come standard with a double-blade cutting head and an integrated saw module. This allows cutting, stripping, and longitudinal slitting to be performed in a single operation. The double blade combines V- and radius blades to ensure precise all-around cuts and enable the processing of a wide variety of cable types. The spring-loaded belt feed guides the cable gently but powerfully – guaranteeing material protection and precise cuts.

The AM 2850 SAW builds on the functions of the AM 2800 SAW and adds a programmable rotary module, particularly suitable for processing coaxial and multi-layer cables. This provides even greater flexibility while maintaining the precision of the saw cut and multi-step stripping. Like all Metzner models, the SAW machines are compatible with all peripherals of the AM 2000 series and ready for cable lists, MES integration, and automated workflows.

Precise Cuts Even with Challenging Cable Types

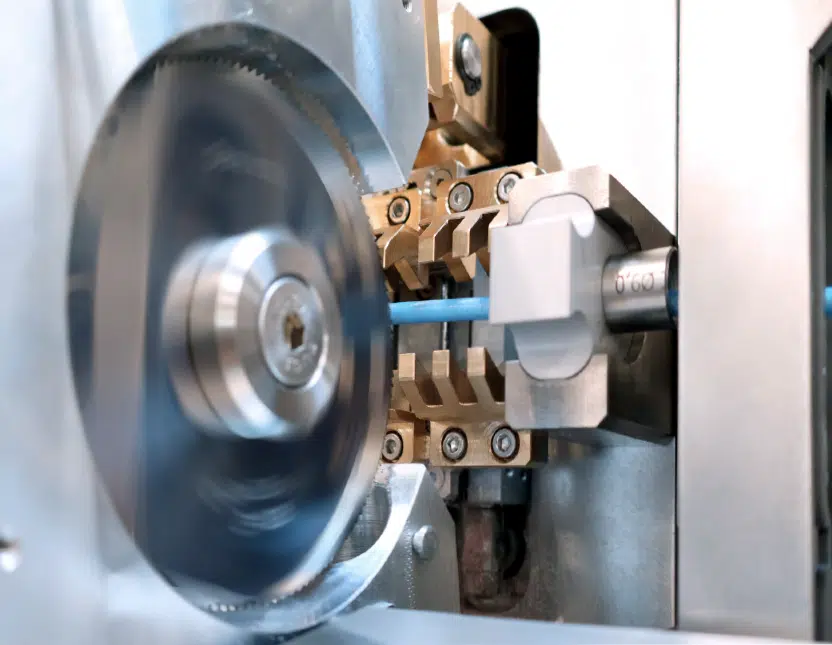

The saw module of the SAW models allows freely programmable blade speeds (1000–4600 rpm) and variable feed rates (1–30 mm/sec). Cables that cannot be processed with conventional blade sets – such as Sucoform, Sucoflex, or POF cables – are cut precisely, squarely, or with a smooth cut surface, without crushing the inner conductor. Standard features include two pneumatic clamping elements and a connection for extraction. Optional additional blade widths and diameters are available, tailored to cable-specific requirements.

Perfect cut

surfaces

without

post-processing

Features & Benefits

- Double-blade cutting head for efficient processing at no extra cost

- Rotary module for complex cables (AM 2850 SAW)

- Saw module with programmable speed for crush-free, square cuts on demanding cable types

- Pneumatic clamping elements and extraction connection standard for clean, vibration-free cut quality

- “All-Inclusive” software with integrated HMI, MES integration, cable list management, and peripheral control

- Flexibly adaptable saw modules with various blade widths and diameters for optimal results on every cable type

Applications

- Cutting cables and wires with saw cut

- Processing coaxial and RF cables

- Cutting Sucoform and Sucoflex cables

- Cutting POF cables

- Cutting stranded and solid conductors

- Cable processing with smooth, square cut surfaces

- Processing sensitive or hard insulation materials

- Printing and marking

Technical Data

| Performance Data | AM 2800 SAW | AM 2850 SAW |

|---|---|---|

| Cable cross-section stranded / solid | 35 mm² | |

| Max. cable diameter | 15 mm | |

| Length interval | 0.1 mm | |

| Typical repeatability | ± (1 mm + 0.2 % l) | |

| Max. feed speed | 180 m/min | |

| Max. stripping length (cable start | cable end) | 0 – 180 mm | 0 – 125 mm | |

| Cable length (min. | max.) | 20 mm | 200,000 mm | |

| Stripping force | 220 N | |

| Saw blade speed | 1,000 – 4,600 rpm (programmable) | |

| Feed speed (saw module) | 1 – 30 mm/s (variable control) | |

| Equipment | AM 2800 SAW | AM 2850 SAW |

|---|---|---|

| Cutting system | Saw blade + double knife | Saw blade + double knife + rotary head |

| Feed system | Belt | |

| Cutting | ✔ (saw cut) | ✔ (saw cut) |

| Stripping full pull | ✔ | ✔ |

| Stripping partial pull | ✔ | ✔ |

| Slitting | ✔ | ✔ |

| Multi-step stripping | 3 steps per cable side | |

| Flat cables | – | – |

| Parts list processing | ✔ | ✔ |

| End-of-material detection | ✔ | ✔ |

| Cable length correction | ✔ | ✔ |

| Recipe management | ✔ | ✔ |

| Length measuring system | optional | optional |

| Interface for printing | optional | optional |

| Interface for peripheral devices | optional | optional |

| IT network interface | optional | optional |

| Rotary cutting unit | – | ✔ |

| Longitudinal slitting module | optional | optional |

| Networking / MES (Industry 4.0) | optional | optional |

| Remote maintenance | PC integrated | PC integrated |

| USB / Ethernet | ✔ | ✔ |

| Saw blade / knives | V-knife, radius V-knife, slitting knife, saw blade | V-knife, radius V-knife, slitting knife, rotary blade, saw blade |

| Number of knife pairs used | 2 | |

| Extraction port on saw module | ✔ (standard integrated) | |

| Technical Data | AM 2800 SAW | AM 2850 SAW |

|---|---|---|

| Dimensions (L × W × H) | 710 × 920 × 350 mm | 960 × 920 × 350 mm |

| Electrical connection | 230 V | 50 Hz | 2 A | |

| Compressed air connection | 6 bar | |

| Weight | 100 kg | 125 kg |

| Control | PLC / PC | |

| Display | 15″ Touchscreen | |

| Power consumption | P: 0.8 kVA | approx. 50 l/min | |

| Noise level (idle) | < 75 dB(A) | |

| Special features (SAW module) | Programmable saw blade speed, precise saw cut without conductor deformation, ideal for Sucoform, Sucoflex, and POF cables | |

Performance Data of AM 2800 SAW / AM 2850 SAW

Cable cross-section stranded / solid35 mm²

Max. cable diameterAM 2800 SAW: 15 mm / AM 2850 SAW: 15 mm

Length interval0.1 mm

Typical repeatability± (1 mm + 0.2 % l)

Max. feed speed180 m/min

Max. stripping length (cable start | cable end)0 – 180 mm | 0 – 125 mm

Cable length (min. | max.)20 mm | 200,000 mm

Stripping force220 N

Saw blade speed1,000 – 4,600 rpm (programmable)

Feed speed (saw module)1 – 30 mm/s (variable control)

Equipment of AM 2800 SAW / AM 2850 SAW

Cutting systemAM 2800 SAW: Saw blade + double knife / AM 2850 SAW: Saw blade + double knife + rotary head

Feed systemBelt

Cutting✔ (saw cut)

Stripping full pull✔

Stripping partial pull✔

Slitting✔

Multi-step stripping3 steps per cable side

Flat cables–

Parts list processing✔

End-of-material detection✔

Cable length correction✔

Recipe management✔

Length measuring systemoptional

Interface for printingoptional

Interface for peripheral devicesoptional

IT network interfaceoptional

Rotary cutting unitonly AM 2850 SAW

Longitudinal slitting moduleoptional

Networking / MES (Industry 4.0)optional

Remote maintenancePC integrated

USB / Ethernet✔

Saw blade / knivesAM 2800 SAW: V-/Radius-/Slitting knife + saw blade / AM 2850 SAW: additionally rotary blade

Number of knife pairs used2

Extraction port on saw module✔ (standard integrated)

Technical Data of AM 2800 SAW / AM 2850 SAW

Dimensions (L×W×H)AM 2800 SAW: 710 × 920 × 350 mm / AM 2850 SAW: 960 × 920 × 350 mm

Electrical connection230 V | 50 Hz | 2 A

Compressed air connection6 bar

WeightAM 2800 SAW: 100 kg / AM 2850 SAW: 125 kg

ControlPLC / PC

Display15″ Touchscreen

Power consumptionAM 2800 SAW: P 0.8 kVA | approx. 50 l/min / AM 2850 SAW: P 0.8 kVA | approx. 50 l/min

Noise level (idle)< 75 dB(A)

Special features (SAW module)Programmable saw blade speed, precise saw cut without conductor deformation, ideal for Sucoform, Sucoflex, and POF cables

ROTARY MODULE

Multilayer-capable. Robust.

Precise, crush-free saw cut

Saw module functions:

- Programmable saw feed speed (1–30 mm/sec)

- Saw blade speed freely selectable (1000–4600 rpm)

- Saw blade diameter 80 mm, widths 0.3 / 0.6 / 0.8 mm

- Two pneumatic clamping elements and extraction port included as standard

METZNER AM 2000 SERIES