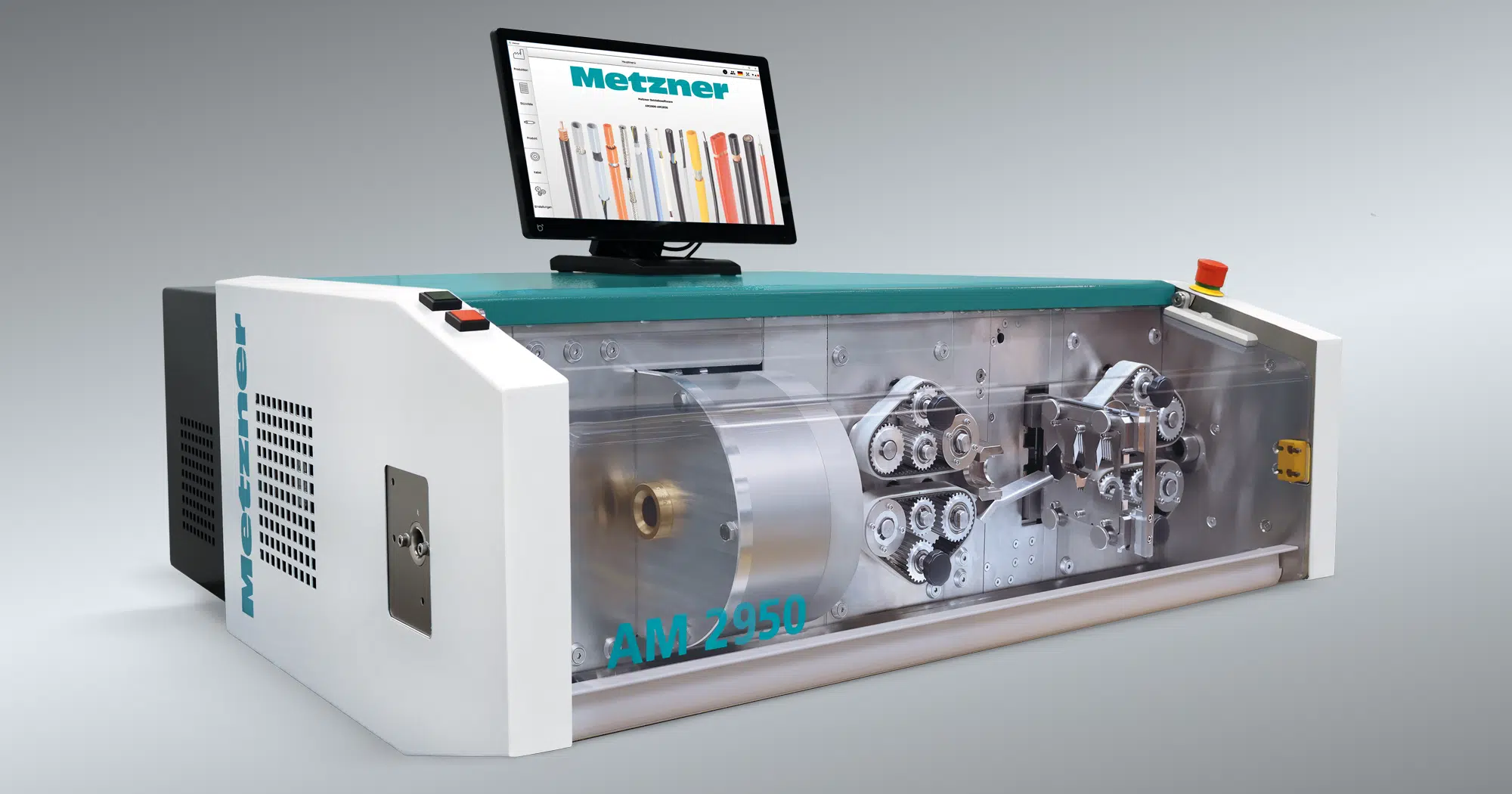

Metzner AM 2900/AM 2950

Maximum versatility and power for cables up to 15 mm Ø and 35 mm²

for cutting, incising, and longitudinal slitting in a single operation

AM 2800 SAW & AM 2850 SAW: Integriertes Sägemodul für sauberen Schnittprozess

Die SAW-Modelle verfügen über ein integriertes Sägemodul, das Quetschung vermeidet und perfekte, rechtwinklige Schnitte liefert. Ideal für Sucoform-, Sucoflex- und POF-Kabel, die sich nicht mit normalen Messersätzen bearbeiten lassen. Die AM 2800 SAW bietet vollautomatische Kabelbearbeitung mit Doppelmesser-Schneidkopf und integriertem Sägemodul, die AM 2850 SAW verfügt zusätzlich über ein Rotativmodul für noch mehr Flexibilität in der Bearbeitung. ChatGPT:AM 2800 SAW & AM 2850 SAW: Integrated saw module for a clean cutting process

The SAW models feature an integrated saw module that prevents deformation and delivers perfect, right-angled cuts. Ideal for Sucoform, Sucoflex, and POF cables that cannot be processed with standard blade sets. The AM 2800 SAW offers fully automatic cable processing with a double-blade cutting head and integrated saw module, while the AM 2850 SAW additionally includes a rotary module for even greater processing flexibility. Du: AM 2800 & AM 2850: Präzise Bearbeitung mit Doppelmesser Die beiden Maschinen sind serienmäßig mit einem Doppelmesser-Schneidkopf ausgestattet, der Ablängen, Abisolieren und Längsschlitzen in einem Arbeitsgang ermöglicht. Der Doppelmesser kombiniert V- und Radiusmesser für präzise Rundum-Schnitte und sorgt für eine vielseitige Kabelbearbeitung ohne zusätzliche Messerwechsel. Die AM 2850 erweitert die Funktionen der AM 2800 um ein Rotativmodul, das Koaxial- und mehrschichtige Kabel hochpräzise bearbeitet und maximale Flexibilität bei komplexen Anwendungen bietet. Ergänzt wird dies durch den gefederten Bandvorschub für schonende Materialführung sowie die „All-Inclusive“-Software der AM 2000 Serie, die vorbereitet ist für Peripheriegeräte, Kabellisten und MES-Anbindungen. ChatGPT: AM 2800 & AM 2850: Precise processing with double-blade technology Both machines come standard with a double-blade cutting head that enables cutting, stripping, and longitudinal slitting in a single operation. The double-blade system combines V and radius blades for precise all-around cuts, providing versatile cable processing without the need for additional blade changes. The AM 2850 extends the capabilities of the AM 2800 with a rotary module that processes coaxial and multilayer cables with high precision, offering maximum flexibility for complex applications. This is complemented by the spring-loaded belt feed for gentle material handling and the “All-Inclusive” software of the AM 2000 series, preconfigured for peripheral devices, cable lists, and MES connectivity. Du:AM 2900 & AM 2950: Mehrfach-Messermodul für maximale Flexibilität

Die AM 2900 und AM 2950 erweitern die AM 2000 Serie um das Mehrfach-Messermodul, das bis zu drei Messerpaare gleichzeitig nutzt. So lassen sich Ablängen, Einschnitt in den Außenmantel und Längsschlitzen in einem Arbeitsgang erledigen. Optional kann auch die Innenleiterbearbeitung mehradriger Kabel integriert werden. Die Maschinen passen sich programmgesteuert an verschiedene Kabeldurchmesser an, wodurch Rüstzeiten minimiert werden. Die AM 2950 verfügt zusätzlich über ein Rotativmodul für die hochpräzise Bearbeitung komplexer und mehrschichtiger Kabel.

ChatGPT:AM 2900 & AM 2950: Multi-blade module for maximum flexibility

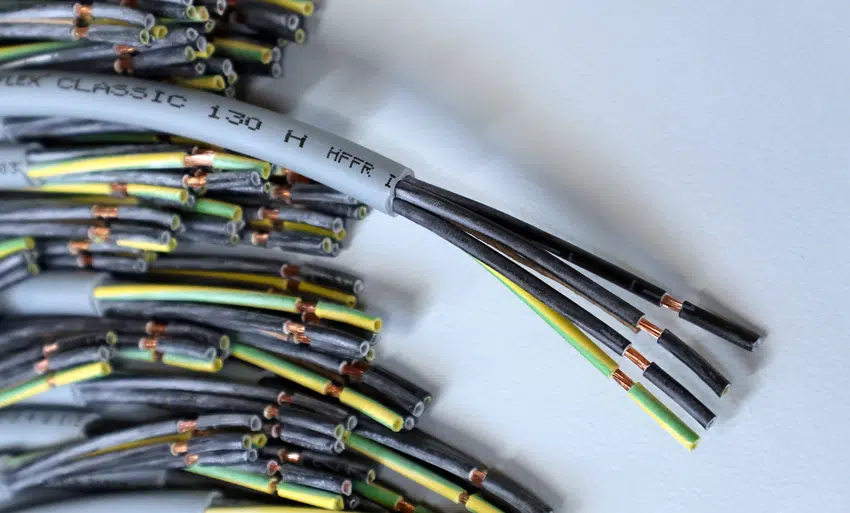

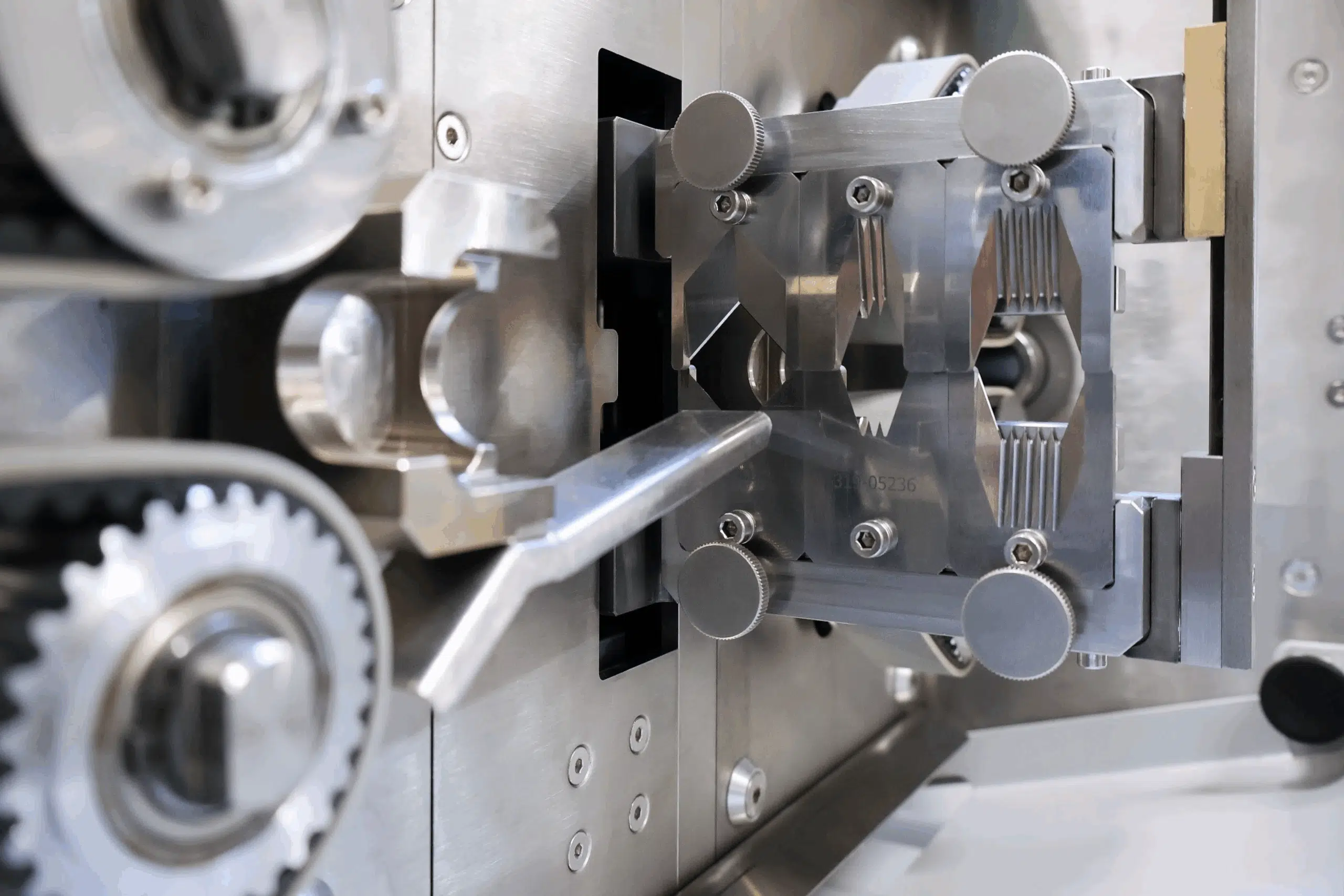

The AM 2900 and AM 2950 expand the AM 2000 series with the multi-blade module, which utilizes up to three blade pairs simultaneously. This allows cutting to length, outer sheath incisions, and longitudinal slitting to be performed in a single operation. Optionally, inner conductor processing for multi-core cables can also be integrated. The machines automatically adjust to different cable diameters via program control, minimizing setup times. The AM 2950 additionally features a rotary module for highly precise processing of complex and multilayer cables.

Du: Schneller. Präziser. Vielseitiger. ChatGPT: Faster. More precise. More versatile. Du: wenn nur text, dann natürlich nur text ChatGPT: Faster. More precise. More versatile. Du:-

- Doppelmesser-Schneidkopf für effiziente Bearbeitung ohne Zusatzkosten

- Rotativmodul für komplexe Kabel (AM 2850/ AM 2950)

- Sägemodul für quetschfreie Schnitte bei schwierigen Kabeltypen (SAW-Modelle)

- Mehrfach-Messermodul für kurze Rüstzeiten und maximale Flexibilität (AM 2900/ AM 2950)

- Gefederte Bandvorschübe für präzise Schnitte trotz Materialschwankungen

- Software „All-Inclusive“: HMI, MES, Peripheriegeräte und Kabellisten serienmäßig

- Innenleiterbearbeitung für mehradrige Kabel (AM 2900/ AM2950)

-

- Double-blade cutting head for efficient processing without extra costs

- Rotary module for complex cables (AM 2850 / AM 2950)

- Saw module for deformation-free cuts on difficult cable types (SAW models)

- Multi-blade module for short setup times and maximum flexibility (AM 2900 / AM 2950)

- Spring-loaded belt feeds for precise cuts despite material variations

- “All-Inclusive” software: HMI, MES, peripheral devices, and cable lists included as standard

- Inner conductor processing for multi-core cables (AM 2900 / AM 2950)

Serienmäßig mit erweiterten Möglichkeiten

Mit einer maximalen Zufuhrgeschwindigkeit von 180 m/min und einem Kabelaußendurchmesser von bis zu 15 mm bearbeitet die AM 2900 Kabel schnell, zuverlässig und wiederholgenau. Die AM 2950 ergänzt das Portfolio durch zusätzliche Bearbeitungsmöglichkeiten mit einem Rotativmodul für besonders komplexe Kabel wie Koaxial- oder Mehrlagenleitungen – hochpräzise, sauber und ohne manuelle Nacharbeit.

Automatische Innenleiter-Bearbeitung

In Verbindung mit dem Mehrfach-Messermodul können die Maschinen mehradrige Kabel mit bis zu sechs Innenleitern automatisch abisolieren. Nach Entfernen des Außenmantels positionieren federgelagerte Klemmbacken die Innenleiter präzise, bevor das Abisoliermesser den Teil- oder Vollabzug durchführt. So werden bisher getrennte Arbeitsgänge zu einem nahtlosen, automatischen Prozess zusammengeführt.

ChatGPT: Versatility on a new level The AM 2900 comes standard with the Metzner multi-blade module, enabling cutting, stripping, and slitting in a single operation. The combination of V and radius blades ensures precise, deformation-free cuts and perfect cable ends — even for longer cable lengths up to 999 m and cross-sections up to 35 mm².Expanded capabilities as standard

With a maximum feed speed of 180 m/min and cable outer diameters up to 15 mm, the AM 2900 processes cables quickly, reliably, and with consistent precision. The AM 2950 extends the portfolio with additional processing options via a rotary module for especially complex cables such as coaxial or multilayer cables — highly precise, clean, and without manual rework.

Automatic inner conductor processing

In combination with the multi-blade module, the machines can automatically strip multi-core cables with up to six inner conductors. After removing the outer sheath, spring-loaded clamping jaws precisely position the inner conductors before the stripping blade performs partial or full stripping. Previously separate steps are thus combined into a seamless, automatic process.

Du: minimale rüstzeit:Flexibel schneiden, schneller produzieren ChatGPT: Minimal setup time:

Cut flexibly, produce faster Du:

-

- Mehrfach-Messermodul für Ablängen, Abisolieren und Schlitzen in einem Arbeitsgang

- Rotativmodul für präzise Bearbeitung von Mehrlagen- und Koaxialkabeln (nur AM 2950)

- Gefederte Bandvorschübe für gleichmäßigen Materialausgleich und präzise Ergebnisse

- Software „All-Inclusive“: HMI, MES, Peripheriegeräte und Kabellisten serienmäßig

- Optionale automatische Innenleiterbearbeitung für mehradrige Kabel

- Breites Einsatzspektrum: Kabelquerschnitt bis 35 mm², Durchmesser bis 15 mm

- Hohe Wiederholgenauigkeit und exakte Endbearbeitung für sofort einsatzbereite Kabel

-

- Multi-blade module for cutting, stripping, and slitting in a single operation

- Rotary module for precise processing of multilayer and coaxial cables (AM 2950 only)

- Spring-loaded belt feeds for uniform material compensation and precise results

- “All-Inclusive” software: HMI, MES, peripheral devices, and cable lists included as standard

- Optional automatic inner conductor processing for multi-core cables

- Wide application range: cable cross-section up to 35 mm², diameter up to 15 mm

- High repeatability and precise end processing for ready-to-use cables

- Schneiden von Kabeln und Litzen

- Abisolieren mit Voll- und Teilabzug

- Fensterabisolierung

- Extrem lange Abzüge in mehreren Schritten

- Abisolieren von mehradrigen Kabeln

- Innenleiter-Abisolierung

- Abisolierung von Flachbandkabeln

- Schneiden und Abisolieren von Teflonkabeln

- Einschneiden und Längsschneiden

- Abisolieren extrem dünner Isolatoren

- Abisolieren von Metallgeflecht mit Schutzkappe

- Mehrstufige Bearbeitung von Koaxialkabeln (nur AM 2950)

- Mehrstufiges Abisolieren

- Ablängen von Drähten

- Bedrucken und Markieren

- Cutting of cables and strands

- Stripping with full and partial removal

- Window stripping

- Extremely long stripping in multiple steps

- Stripping of multi-core cables

- Inner conductor stripping

- Stripping of flat ribbon cables

- Cutting and stripping of Teflon cables

- Incising and longitudinal cutting

- Stripping extremely thin insulations

- Stripping braided metal with protective cap

- Multi-step processing of coaxial cables (AM 2950 only)

- Multi-step stripping

- Cutting wires to length

- Printing and marking

| Leistungsdaten | AM 2900 | AM 2950 |

|---|---|---|

| Kabelquerschnitt Litze / Volldraht | 0,5 – 35 mm² | |

| Kabeldurchmesser max. | 15 mm | |

| Längenintervall | 0.1 mm | |

| Typische Wiederholgenauigkeit | ± (1 mm + 0.2 % l) | |

| Vorschubgeschwindigkeit max. | 180 m/min | |

| Abisolierlänge max. (Kabelanfang | Kabelende) | 0 – 180 mm | 0 – 125 mm | |

| Kabellänge (min. | max.) | 75 mm | 999 m | |

| Drahtabisolierkraft | 220 N | |

| Ausstattung | AM 2900 | AM 2950 |

|---|---|---|

| Schneidsystem | Mehrfach-Messermodul | Mehrfach-Messermodul + Rotativkopf |

| Vorschubsystem | Band | |

| Ablängen | ✔ | ✔ |

| Abisolieren mit Vollabzug | ✔ | ✔ |

| Abisolieren mit Teilabzug | ✔ | ✔ |

| Schlitzen | ✔ | ✔ |

| Mehrstufiges Abisolieren | 3 Stufen je Kabelseite | |

| Flachkabel | – | – |

| Stücklistenbearbeitung | ✔ | ✔ |

| Materialenderkennung | ✔ | ✔ |

| Kabellängenkorrektur | ✔ | ✔ |

| Rezeptdatenverwaltung | ✔ | ✔ |

| Längenmesssystem | optional | optional |

| Schnittstelle für Bedruckung | optional | optional |

| Schnittstelle für Peripheriegeräte | optional | optional |

| IT-Netzwerkschnittstelle | optional | optional |

| Rotationsschneideeinheit | – | ✔ |

| Längenschlitzmodul | optional | optional |

| Vernetzung / MES (Industrie 4.0) | optional | optional |

| Fernwartung | PC integriert | PC integriert |

| USB / Ethernet | ✔ | ✔ |

| Messer | V-Messer, Radius-V-Messer, Schlitzmesser | V-Messer, Radius-V-Messer, Schlitzmesser, Rotativklinge |

| Anzahl der verwendeten Messerpaare | 2 | |

| Technische Daten | AM 2900 | AM 2950 |

|---|---|---|

| Abmessungen (L × B × H) | 710 × 920 × 350 mm | 960 × 920 × 350 mm |

| Elektrischer Anschluss | 230 V | 50/60 Hz | 2 A | |

| Druckluftanschluss | 6 bar | 6 bar |

| Gewicht | 100 kg | 125 kg |

| Steuerung | SPS / PC | |

| Anzeige | 15″ Touchscreen | |

| Verbrauch | P: 0,8 kVA | ca. 50 l/min | |

| Geräuschentwicklung (Leerlauf) | < 75 dB(A) | |

| Besonderheiten | Mehrfach-Messermodul für Ablängen, Abisolieren, Schlitzen in einem Schritt; Erweiterung Innenleiterbearbeitung möglich | |

| Performance Data | AM 2900 | AM 2950 |

|---|---|---|

| Cable cross-section strand / solid wire | 0.5 – 35 mm² | |

| Maximum cable diameter | 15 mm | |

| Length interval | 0.1 mm | |

| Typical repeatability | ± (1 mm + 0.2 % l) | |

| Maximum feed speed | 180 m/min | |

| Maximum stripping length (cable start | cable end) | 0 – 180 mm | 0 – 125 mm | |

| Cable length (min. | max.) | 75 mm | 999 m | |

| Wire stripping force | 220 N | |

| Features | AM 2900 | AM 2950 |

|---|---|---|

| Cutting system | Multi-blade module | Multi-blade module + rotary head |

| Feed system | Belt | |

| Cut to length | ✔ | ✔ |

| Full-strip stripping | ✔ | ✔ |

| Partial-strip stripping | ✔ | ✔ |

| Slitting | ✔ | ✔ |

| Multi-step stripping | 3 steps per cable side | |

| Flat cable | – | – |

| Bill of materials processing | ✔ | ✔ |

| Material end detection | ✔ | ✔ |

| Cable length correction | ✔ | ✔ |

| Recipe data management | ✔ | ✔ |

| Length measuring system | optional | optional |

| Interface for printing | optional | optional |

| Interface for peripheral devices | optional | optional |

| IT network interface | optional | optional |

| Rotary cutting unit | – | ✔ |

| Longitudinal slitting module | optional | optional |

| Networking / MES (Industry 4.0) | optional | optional |

| Remote maintenance | PC integrated | PC integrated |

| USB / Ethernet | ✔ | ✔ |

| Blades | V-blade, radius V-blade, slitting blade | V-blade, radius V-blade, slitting blade, rotary blade |

| Number of blade pairs used | 2 | |

| Technical Data | AM 2900 | AM 2950 |

|---|---|---|

| Dimensions (L × W × H) | 710 × 920 × 350 mm | 960 × 920 × 350 mm |

| Electrical connection | 230 V | 50/60 Hz | 2 A | |

| Compressed air connection | 6 bar | 6 bar |

| Weight | 100 kg | 125 kg |

| Control | PLC / PC | |

| Display | 15″ Touchscreen | |

| Consumption | P: 0.8 kVA | approx. 50 l/min | |

| Noise level (idle) | < 75 dB(A) | |

| Special features | Multi-blade module for cutting, stripping, and slitting in one step; inner conductor processing upgrade possible | |

- Abisolieren erfolgt nach dem Entfernen des Außenmantels

- Federgelagerte Klemmbacken richten die Innenleiter präzise aus

- Vollabzug inklusive automatischer Entsorgung der Abfallstücke

- Arbeitsgänge für Außenmantel und Innenleiter werden kombiniert

- Stripping is performed after removing the outer sheath

- Spring-loaded clamping jaws precisely align the inner conductors

- Full-strip including automatic disposal of scrap pieces

- Operations for outer sheath and inner conductors are combined

to different cable diameters reduces setup times

for gentle, secure cable guidance

everything you need for cable processing

With multi-blade module for cutting, stripping & slitting in a single pass

Expanded capabilities as standard

With a maximum feed speed of 180 m/min and cable outer diameters up to 15 mm, the AM 2900 processes cables quickly, reliably, and with consistent precision. The AM 2950 extends the portfolio with additional processing options via a rotary module for especially complex cables such as coaxial or multilayer cables — highly precise, clean, and without manual rework.

Automatic inner conductor processing

In combination with the multi-blade module, the machines can automatically strip multi-core cables with up to six inner conductors. After removing the outer sheath, spring-loaded clamping jaws precisely position the inner conductors before the stripping blade performs partial or full stripping. Previously separate steps are thus combined into a seamless, automatic process.

Minimal setup time:

Cut flexibly, produce faster

Features & Benefits

- Multi-blade module for cutting, stripping, and slitting in a single operation

- Rotary module for precise processing of multilayer and coaxial cables (AM 2950 only)

- Spring-loaded belt feeds for uniform material compensation and precise results

- “All-Inclusive” software: HMI, MES, peripheral devices, and cable lists included as standard

- Optional automatic inner conductor processing for multi-core cables

- Wide application range: cable cross-section up to 35 mm², diameter up to 15 mm

- High repeatability and precise end processing for ready-to-use cables

Applications

- Cutting of cables and strands

- Stripping with full and partial removal

- Window stripping

- Extremely long stripping in multiple steps

- Stripping of multi-core cables

- Inner conductor stripping

- Stripping of flat ribbon cables

- Cutting and stripping of Teflon cables

- Incising and longitudinal cutting

- Stripping extremely thin insulations

- Stripping braided metal with protective cap

- Multi-step processing of coaxial cables (AM 2950 only)

- Multi-step stripping

- Cutting wires to length

- Printing and marking

Technical Data

| Performance Data | AM 2900 | AM 2950 |

|---|---|---|

| Cable cross-section strand / solid wire | 0.5 – 35 mm² | |

| Maximum cable diameter | 15 mm | |

| Length interval | 0.1 mm | |

| Typical repeatability | ± (1 mm + 0.2 % l) | |

| Maximum feed speed | 180 m/min | |

| Maximum stripping length (cable start | cable end) | 0 – 180 mm | 0 – 125 mm | |

| Cable length (min. | max.) | 75 mm | 999 m | |

| Wire stripping force | 220 N | |

| Features | AM 2900 | AM 2950 |

|---|---|---|

| Cutting system | Multi-blade module | Multi-blade module + rotary head |

| Feed system | Belt | |

| Cut to length | ✔ | ✔ |

| Full-strip stripping | ✔ | ✔ |

| Partial-strip stripping | ✔ | ✔ |

| Slitting | ✔ | ✔ |

| Multi-step stripping | 3 steps per cable side | |

| Flat cable | – | – |

| Bill of materials processing | ✔ | ✔ |

| Material end detection | ✔ | ✔ |

| Cable length correction | ✔ | ✔ |

| Recipe data management | ✔ | ✔ |

| Length measuring system | optional | optional |

| Interface for printing | optional | optional |

| Interface for peripheral devices | optional | optional |

| IT network interface | optional | optional |

| Rotary cutting unit | – | ✔ |

| Longitudinal slitting module | optional | optional |

| Networking / MES (Industry 4.0) | optional | optional |

| Remote maintenance | PC integrated | PC integrated |

| USB / Ethernet | ✔ | ✔ |

| Blades | V-blade, radius V-blade, slitting blade | V-blade, radius V-blade, slitting blade, rotary blade |

| Number of blade pairs used | 2 | |

| Technical Data | AM 2900 | AM 2950 |

|---|---|---|

| Dimensions (L × W × H) | 710 × 920 × 350 mm | 960 × 920 × 350 mm |

| Electrical connection | 230 V | 50/60 Hz | 2 A | |

| Compressed air connection | 6 bar | 6 bar |

| Weight | 100 kg | 125 kg |

| Control | PLC / PC | |

| Display | 15″ Touchscreen | |

| Consumption | P: 0.8 kVA | approx. 50 l/min | |

| Noise level (idle) | < 75 dB(A) | |

| Special features | Multi-blade module for cutting, stripping, and slitting in one step; inner conductor processing upgrade possible | |

Automatic inner conductor processing

- Stripping is performed after removing the outer sheath

- Spring-loaded clamping jaws precisely align the inner conductors

- Full-strip including automatic disposal of scrap pieces

- Operations for outer sheath and inner conductors are combined

MULTI-BLADE MODULE

Efficiency. Time savings. Reliability.

METZNER AM 2000 SERIES