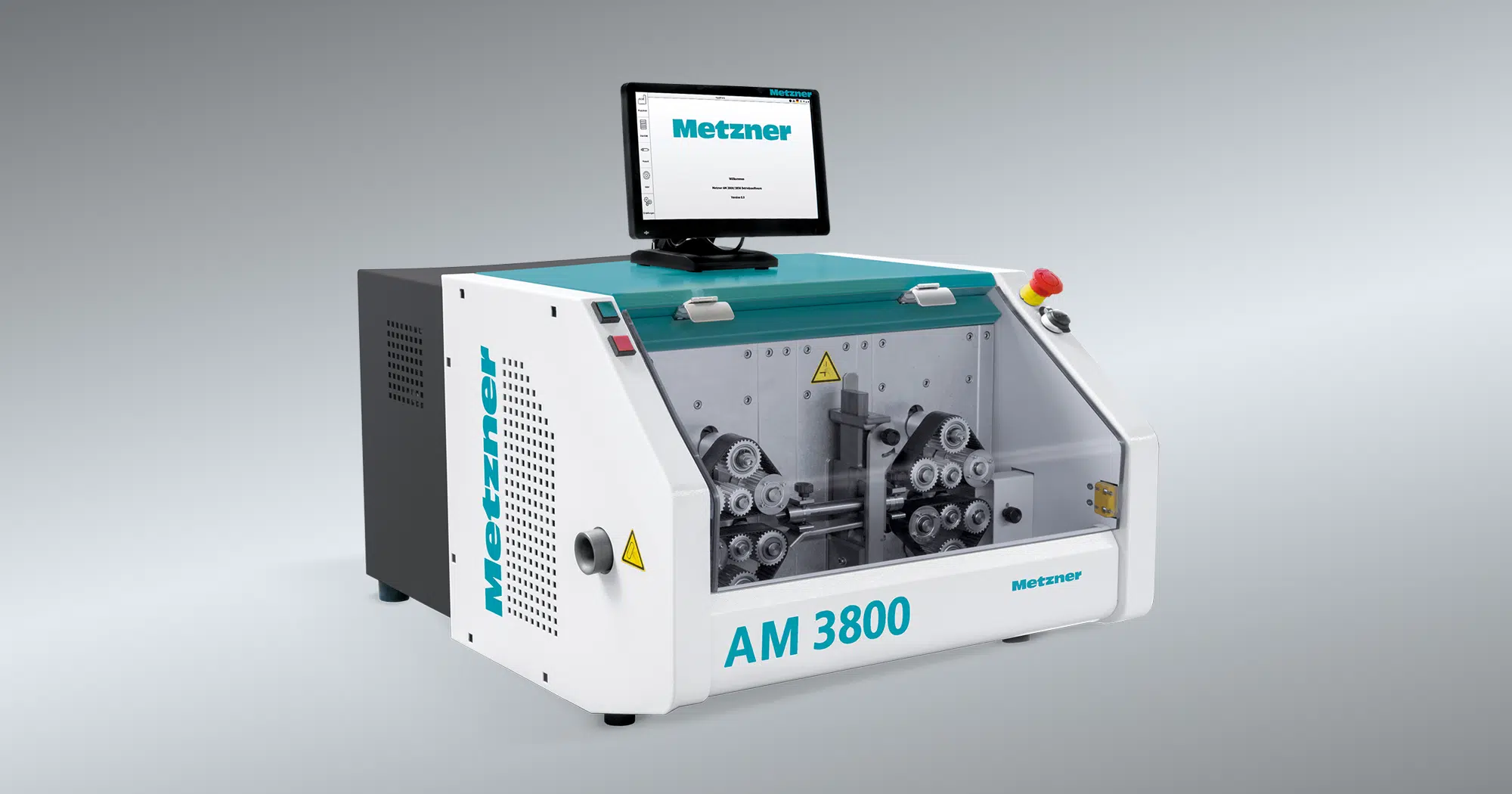

Metzner AM 3000 SERIES

Best choice for cables up to 20 mm ∅ & 70 mm² cross-section

with cross-sections from 0.5 mm² to 70 mm²

thanks to pneumatic belt guidance

for demanding and complex cable processing

with cross-sections from 0.5 mm² to 70 mm²

and even more powerful engines

for additional versatility and multi-stage cable processing

Maximum Performance & Versatility

The machines in this series offer the ideal solution for demanding cable applications by combining advanced technology with high flexibility and performance. Thanks to the Metzner Long-Life Design, you benefit from maximum reliability, minimal maintenance, and an excellent ROI.

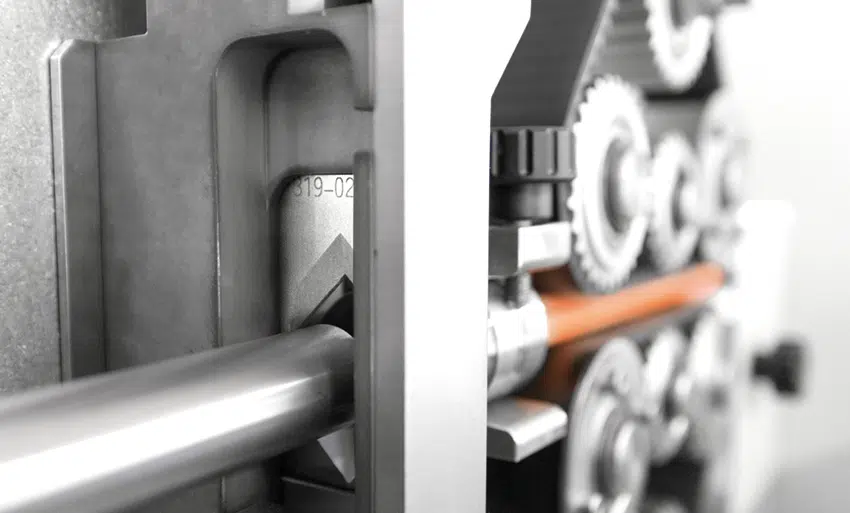

Standard Double Blade Cutting System

All models in the Metzner AM 3000 series are equipped as standard with the patented double blade cutting system, which opens up additional processing possibilities. By combining two pairs of blades – such as V-blades, radius blades, or slit blades – processing options are created that would not be feasible with a conventional single blade head.

The machines cover the entire spectrum from 0.5 to 70 mm² – without costly additional options. Changing blades and guides is tool-free, significantly reducing setup times and making operation even more efficient.

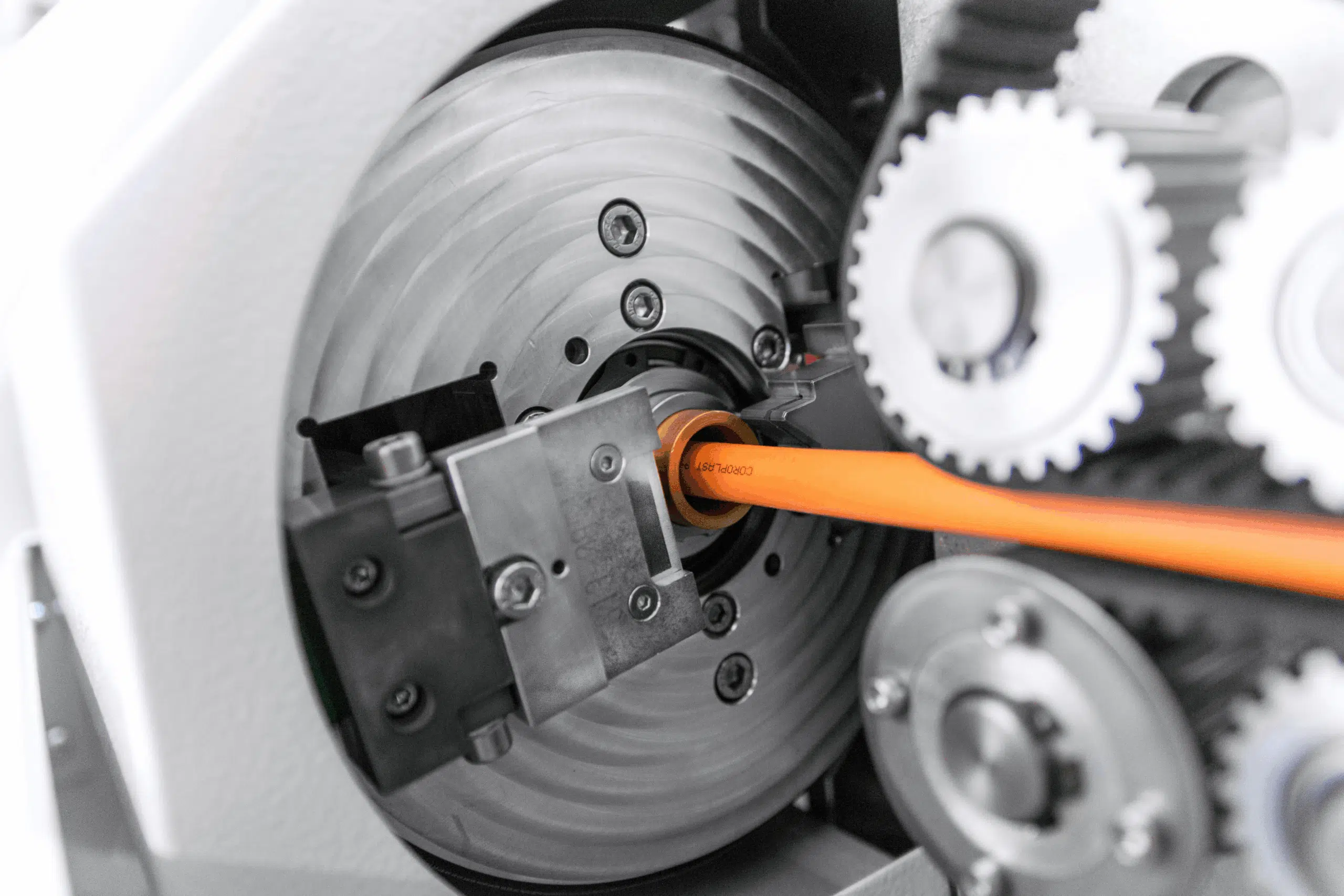

Maximum performance in cutting to length and stripping – Robust and durable

The Metzner AM 3000 machines are equipped with the most powerful motors in their category and deliver up to 40% more cutting force than comparable models. This allows them to effortlessly process large cross-sections up to 70 mm².

Thanks to the extra-long belt drives, motor power is transmitted evenly and gently to the cable. This ensures precise cuts and a long service life for the components. The pneumatic feed ensures particularly material-friendly handling with minimal slip and achieves repeat accuracies of ±1 mm at feed speeds of up to 180 m/min.

Fully equipped software – ready for any application

Full software equipment is standard in the AM 3000 series. MES and PC integration, BOM program, and interfaces for printers and peripheral devices are included as standard. This means the machines are immediately ready for use and ideally designed for all types of pre- and post-processing – without expensive additional modules.

Future-proof and adaptable

The design of the AM 3000 series is built for longevity and stability. Important components are generously dimensioned to ensure reliable continuous operation. Software updates can be conveniently installed remotely by Metzner service upon request.

Furthermore, each machine can be flexibly adapted to individual requirements – for example, with modules for inner conductor stripping or the rotary cutting unit, which is already integrated as standard in the AM 3850.

Up to 40% more cutting power than other models

Features & Benefits

- Standard double blade cutting system for more processing options

- Power for 70 mm² – No costly additional options necessary

- Tool-free change of blades and guides

- Prepared for all types of peripheral devices for pre- and post-processing, transforming a single machine into an automated line.

- Prepared as standard for MES or IT network integration.

- Prepared for all types of peripheral devices for pre- and post-processing, transforming a single machine into an automated line.

Applications

- Cutting of cables and strands

- Stripping with full and partial pull-off

- Window stripping

- Extremely long pull-offs in multiple steps

- Stripping of multi-core cables

- Stripping of flat ribbon cables

- Cutting and stripping of Teflon cables

- Notching and slitting

- Stripping of extremely thin insulation

- Stripping of metal braiding with protective cap

- Multi-step processing of coaxial cables (AM 3850 only)

- Multi-step stripping

- Cutting wires to length

- Printing and marking

Technical Data

| Performance Data | AM 3800 | AM 3850 |

|---|---|---|

| Wire size range stranded/solid | 70 mm² | |

| Cable diameter max. | 20 mm | |

| Length interval | 0.1 mm | |

| Typical repeat accuracy | ± (1mm + 0.2 % l) | |

| Feeding speed max. | 590 ft/min | |

| Stripping length max. (Cable start | Cable end) | 0–200 mm | 0–145 mm | 0–200 mm | 0–145 mm |

| Cable length (min. | max.) | 70 mm | 999 mm | |

| Wire stripping force | 250 N | |

| Equipment | AM 3800 | AM 3850 |

|---|---|---|

| Cutting system | Knife | Knife and rotary unit |

| Feeding system | Belt | |

| Cutting | ✔ | ✔ |

| Stripping with full pull-off | ✔ | ✔ |

| Stripping with partial pull-off | ✔ | ✔ |

| Slitting | ✔ | ✔ |

| Multistage stripping | 3 stages on each side | |

| Ribbon cable | – | – |

| BOM processing | ✔ | ✔ |

| Material end recognition | ✔ | ✔ |

| Cable length compensation | ✔ | ✔ |

| Recipe data management | ✔ | ✔ |

| Length measuring system | option | option |

| Printing interface | option | option |

| Interface for peripherals | option | option |

| IT network interface | option | option |

| Rotary cutting unit | – | ✔ |

| Length slitting unit | option | option |

| Networking / MES interface (Industry 4.0) | option | option |

| Remote servicing | PC integrated | PC integrated |

| USB / Ethernet | ✔ | ✔ |

| Blades | V blade, Radius V blade, Slitting blade | V blade, Radius V blade, Slitting blade, Rotary blade |

| Number of pairs of blades in use | 2 | |

| Technical Data | AM 3800 | AM 3850 |

|---|---|---|

| Dimensions (L × W × H) | 691 × 788 × 926 mm | 928 × 788 × 926 mm |

| Electrical connection | 230 V | 50 Hz | |

| Compressed air connection | 6 bar | |

| Weight | 130 kg | 160 kg |

| Drive | SPS / PC | |

| Display | 15“ touch screen | |

| Consumption | 0.8 kVA | approx. 50 l/min | |

| Noise (idle) | < 75 dB(A) | |

Maximum ROI through innovative design

Metzner machines are designed for long-term industrial use and, once run in, operate precisely and reliably for years. The low-maintenance design, high cutting quality, and flexible expandability ensure that your investment quickly pays for itself – and creates added value in the long term.

METZNER AM 3000 SERIES

Precision. Performance. Durability.

METZNER AM 3000 SERIES