STANDARD MACHINES ADAPTED TO YOUR NEEDS

Whether peripherals or software changes - a Metzner cable cutting machine matching your production

1. Metzner has its own department for PLC and HMI programming. It is therefore possible to adapt your automatic cable cutting machine to your needs. For example, if it is necessary for the cable to stop during production or, on the contrary, to continue moving, if a scan is required, or if the operator is to carry out another work step, etc., etc., etc.

Our team will then program the software for you in the way that best suits your work processes.

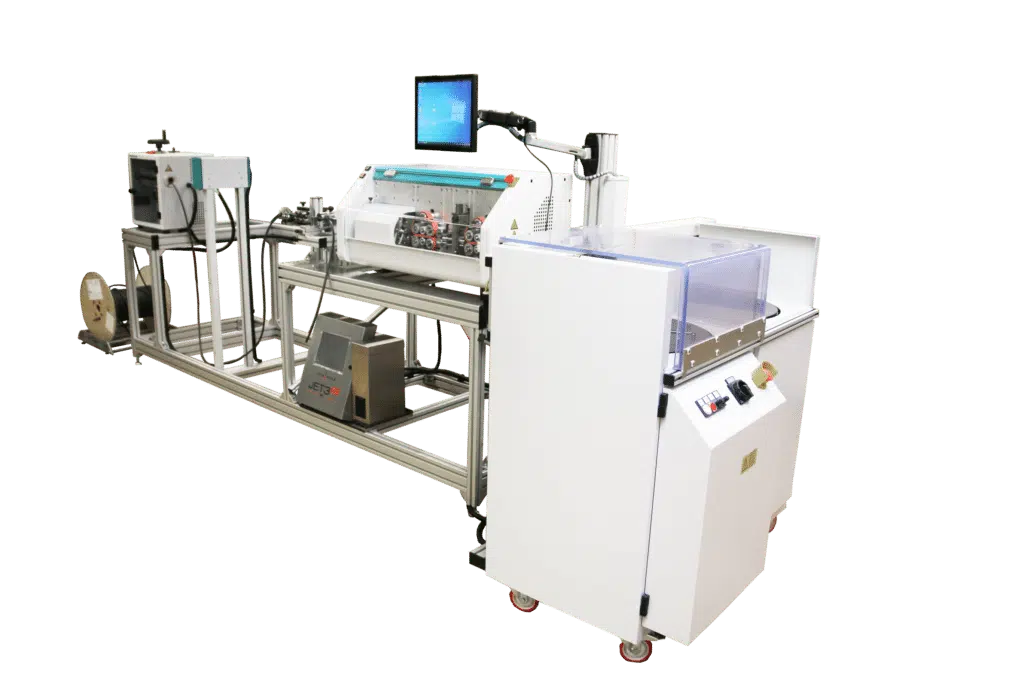

2. Of course, we supply your machine complete with pre-processing and post-processing systems. These include precisely matching active or passive feeding systems, single or duo ring winders or stackers. For printing or marking the cables, we offer you solutions with ink, laser or as printed film for marking, which is automatically glued.

Also peripherials are customizeable.

Examples of machine adaptations

Line of standard machines with adapted software

Line of standard machines with Cleaning Station

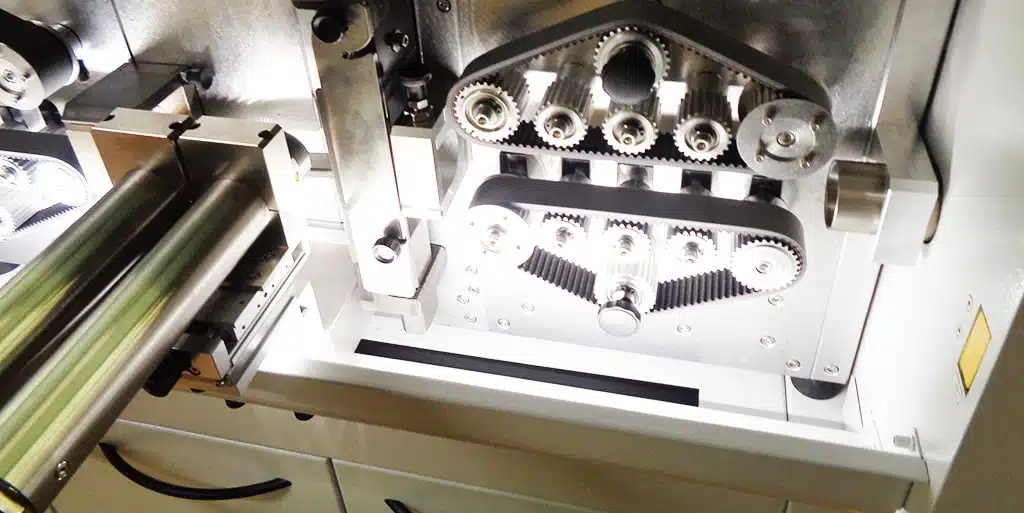

Standard machine with printing on the cables on the swivel tube for fewer bad parts

If the printing is only done on the swivel tube, the investment is higher, but the cable waste is significantly reduced. If you would also like to take advantage of this solution, simply send us a mail.