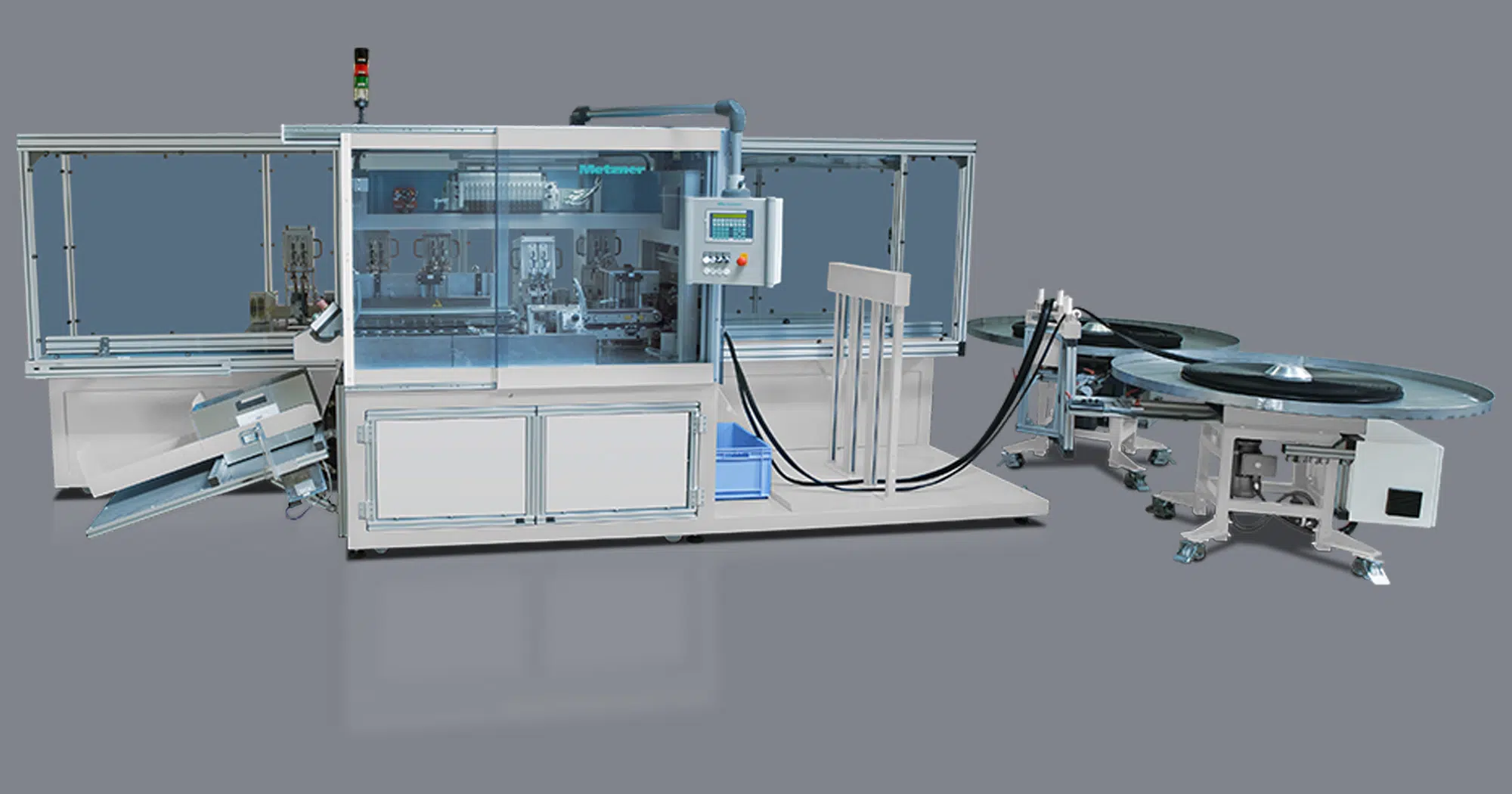

SINGLE PASS CUTTING UNIT FOR SEALING PROFILES

Contour cutting included, the Automatic Single-Pass cutting machines

These Automatic One-Step machines are especially developped for complex processes as they are required in the production of sealing profiles for cars, applications for furniture, thermal insulations or profiles for household goods.

Whether cutting, drilling or milling, all can be performed in just one step. The machines are piloted by the data read from a barcode scanner. Thanks to this data, the operator can read from the display which tools and materials are necessary. Changeovers of tools can be performed in less than 30 seconds.

The machine knows the quantities, forms and lenghts to be produced. It also checks automatically that the right tool is used.

APPLICATIONS

No matter what industry, sealing profiles have a complex geometry. The SPCM cuts, drills and mills the raw material exactly to the desired gasket profile in just one step. The work steps:

1. Scan of the Production documents

The built-in-scanner reads the production paperwork and knows material, quantity, geometry and lenght of the material to be produced.

2. Instruction of the operator

On the display, the operator can see, which material and which tool to use. Changeovertimes are less than 30 seconds.

3. The machine’s test

Automatically, the machine checks the tooling to ensure the right one is in place.

4. Production

After that, the production runs automatically.