TURNING A SINGLE MACHINE INTO A LINE

peripherials for pre-processing as well as post-processing

Cable processing peripherals increase both the efficiency and the quality of the output of your processing machine. In our program, as well as in the portfolio of our subsidiary Ramatech, you will find all solutions needed to turn a single machine into an efficient processing line: Metzner offers you a comprehensive range of cable processing peripherals – both for pre-processing and post-processing.

Peripherals for Pre-Processing

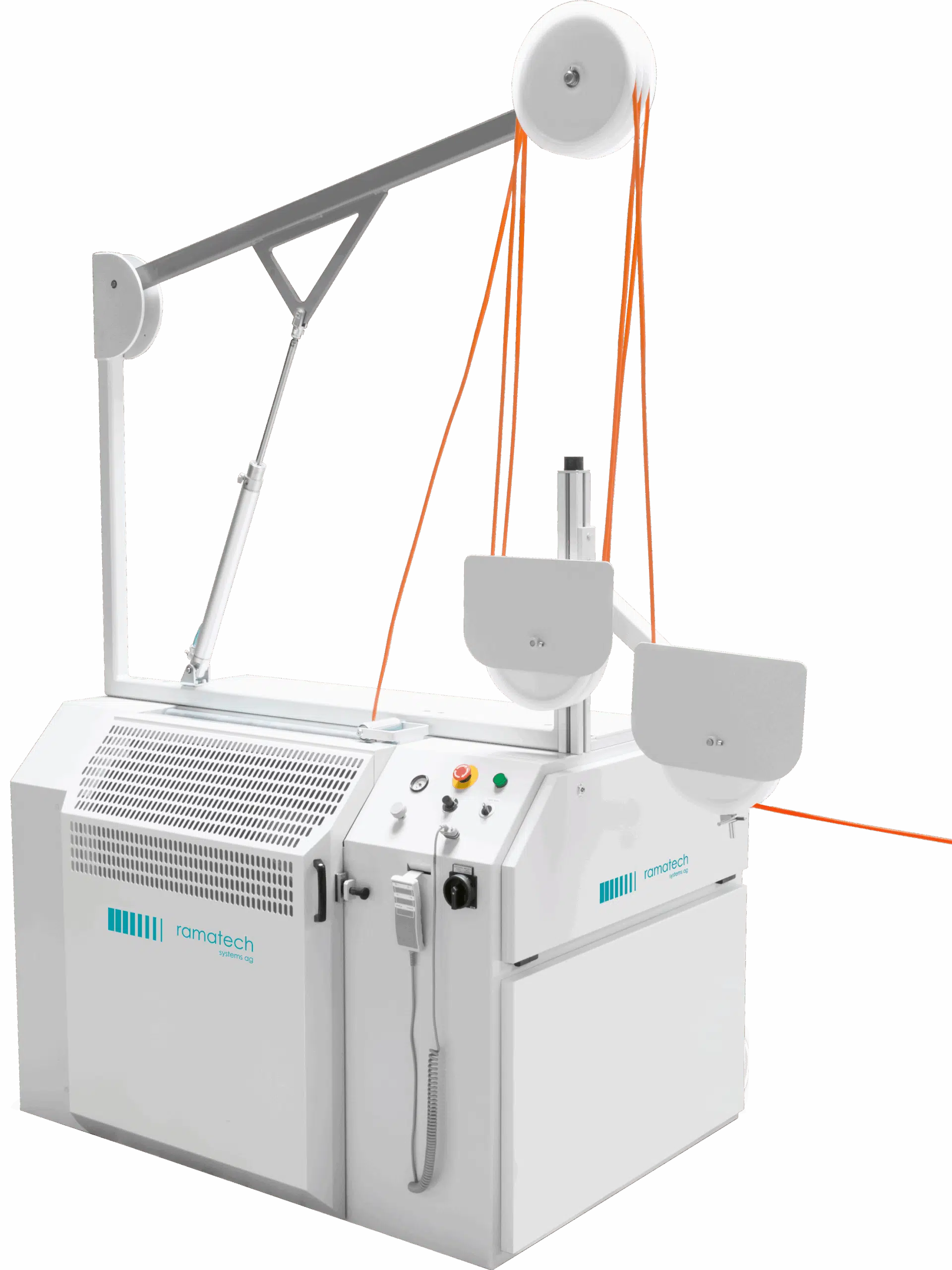

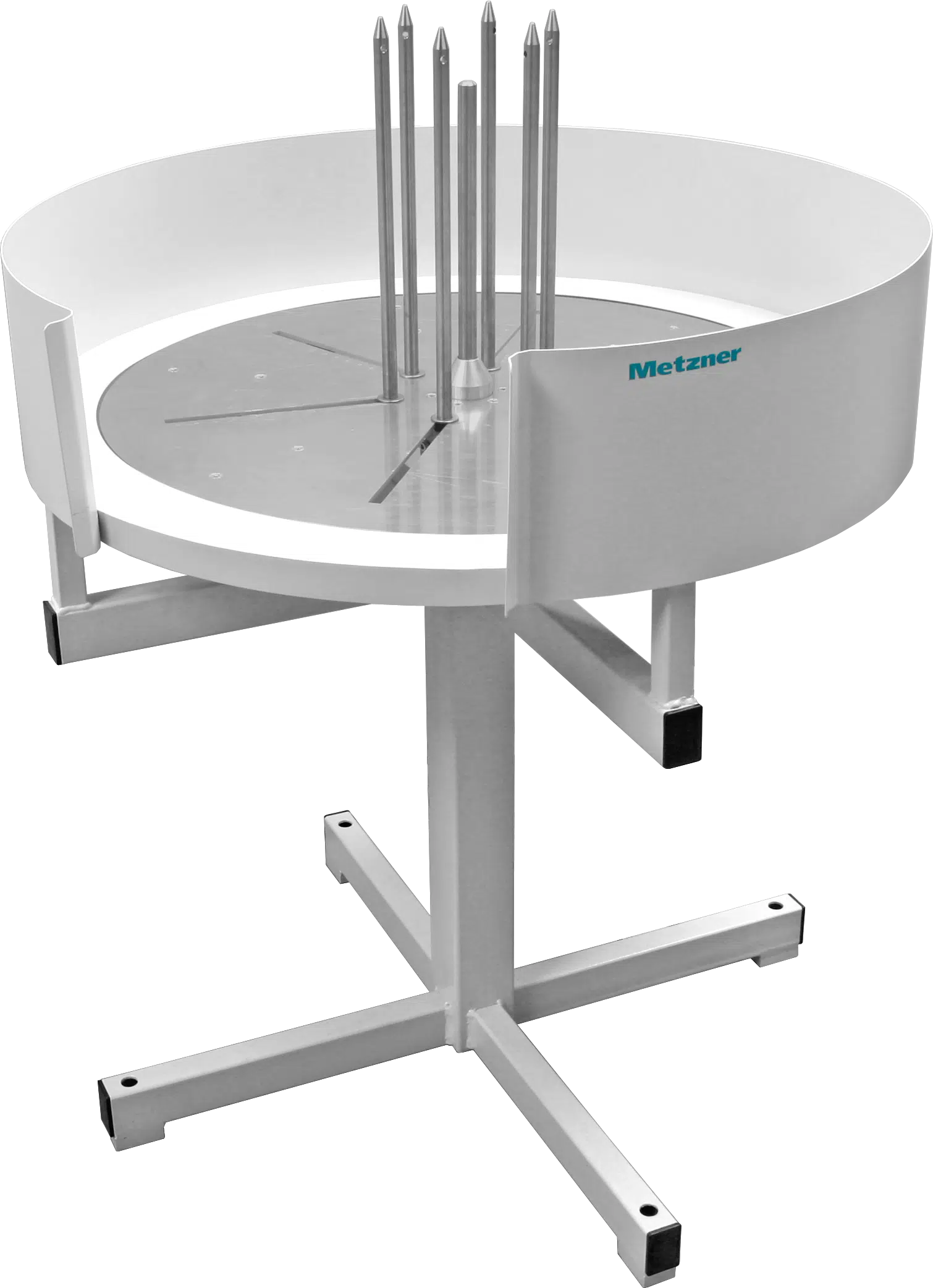

The pre-processing portfolio includes electrically driven dereelers, passive dereelers, and prefeeder units. The electrically driven dereelers are supplied by our sister company Ramatech. They are easy to operate and protect the operator’s health, since the cable drum can be positioned using a lift, for example. Passive dereelers from Metzner are available for cables wound on heavy drums, on reels, from cardboard boxes, or in loose bundles. Prefeeders are used to guide the cable from the passive dereeler to the cutting machine without tension. Metzner offers these either with a dancer arm or in combination with loop control.

Peripherals for Post-Processing

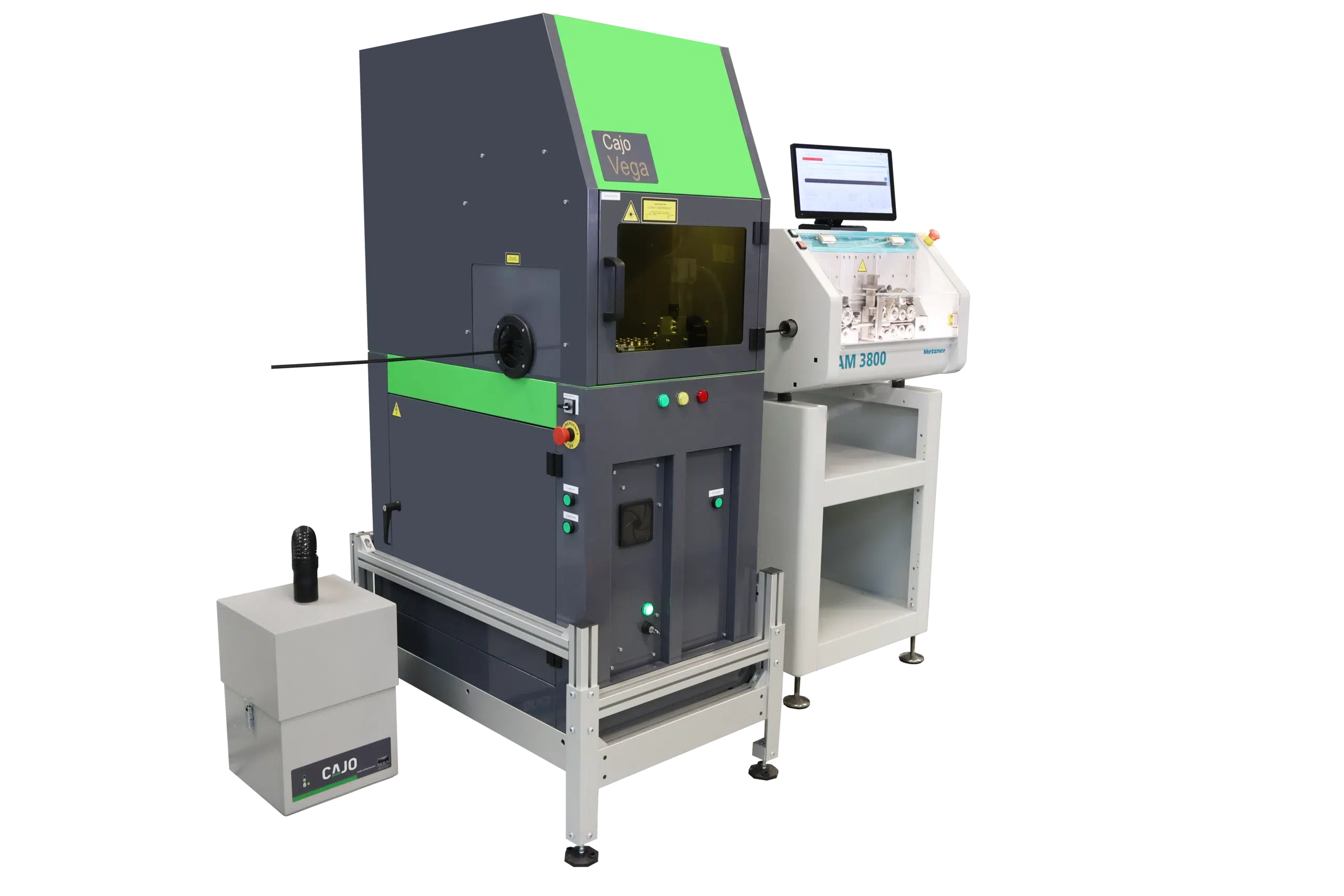

For post-processing, Metzner offers active cable stackers for lengths between 2 m and 6 m (6’7″ to 19’8″). As cable ring winders, we offer you the models from our sister company Ramatech. These wind the cable into coils, coil and bind it, or coil, bind, and then place it down. In addition, we offer the Metzner CRC 450 DUO, which is equipped with two ring winders that operate alternately.